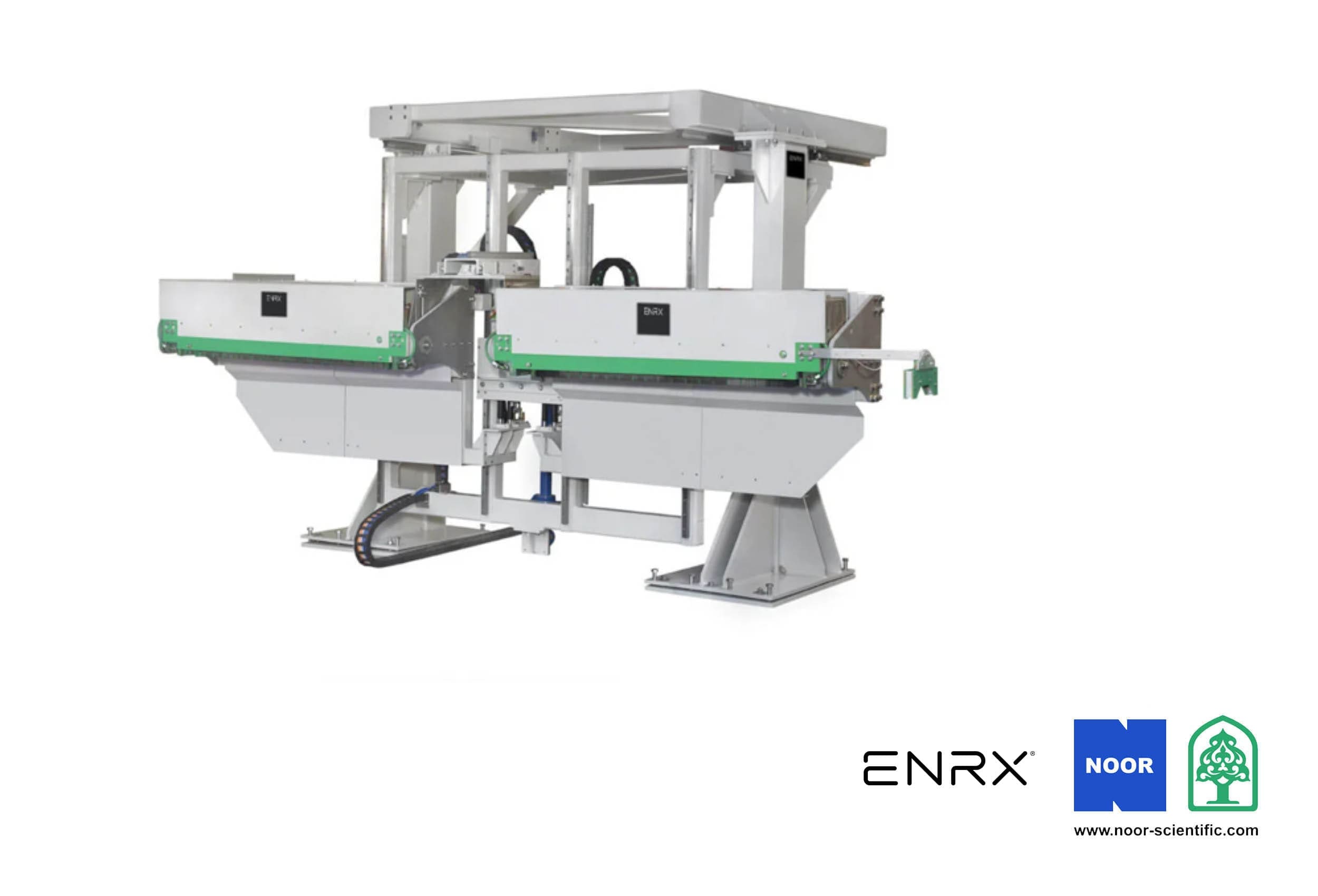

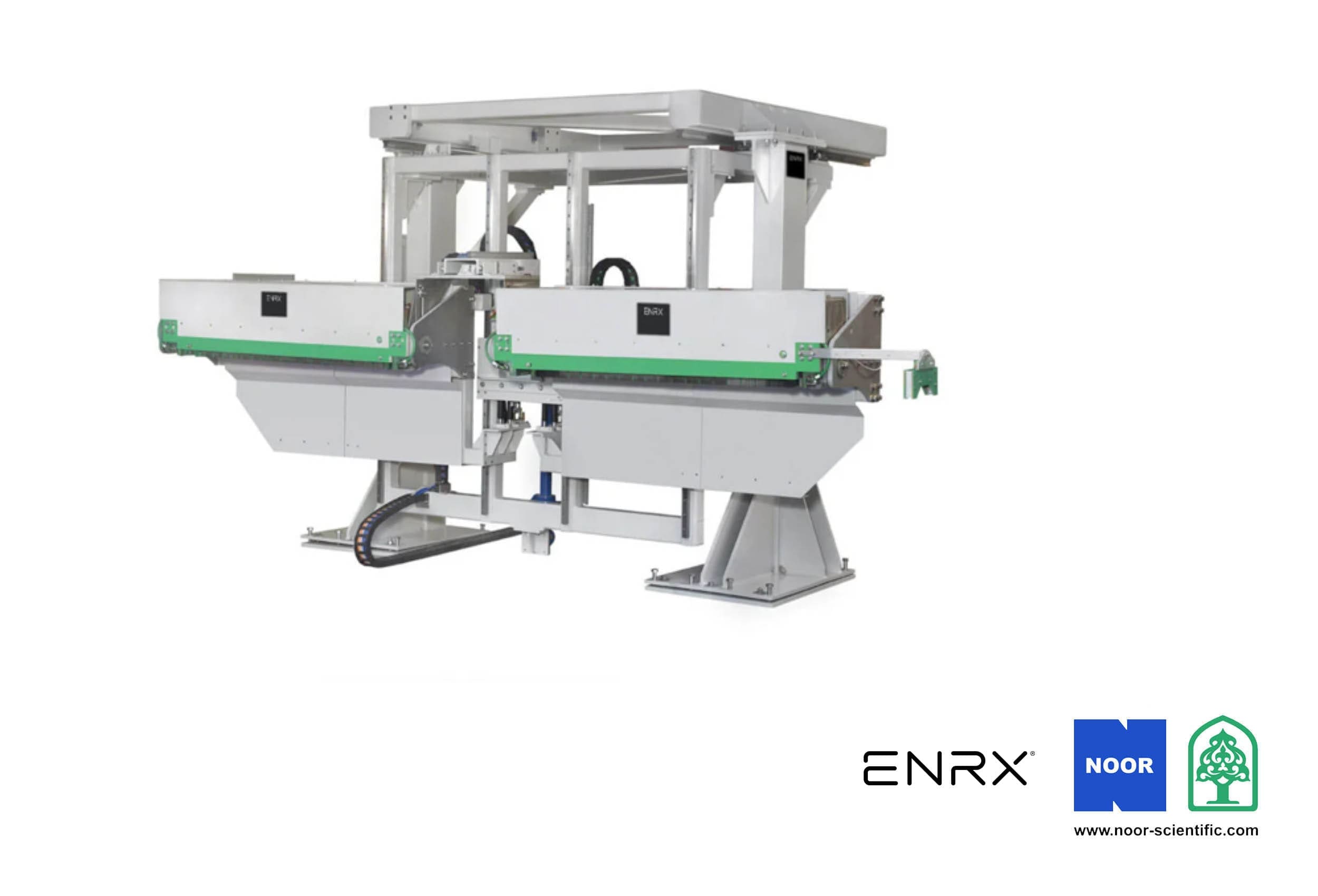

Seam Normalizing Systems

Induction-based seam normalizing systems designed for longitudinally welded pipes, providing precise, controllable and efficient heat treatment for oil and gas

This system uses controlled & localized induction heating to rapidly disbond coatings from metal substrates. Eddy currents heat the steel beneath the coating, allowing the coating to be lifted off cleanly without abrasives, dust, or contaminants.

The system dramatically reduces coating removal time—up to 90% faster than abrasive blasting or grinding. It enhances environmental safety by reducing fumes, eliminating blast media, and enabling clean removal where coating flakes can simply be swept or vacuumed. The process is virtually noiseless and ideal for public or urban work sites.

The system supports multiple heating modes, including spot heating, scanning, semi-automatic, and manual operation. It is built for rugged industrial environments, offers long equipment life, The system ensures safe operation with water-cooled, low-voltage HHT units, and supports the optional i-Scan system for automatic adaptation to coating thickness and operator movement.

The system is engineered for industry safety, environmental and operational standards.

Induction-based seam normalizing systems designed for longitudinally welded pipes, providing precise, controllable and efficient heat treatment for oil and gas

An induction-based system for fast, safe and precise expansion of bolts used in turbines and heavy-duty assemblies.

A stationary induction heating system delivering precise, contactless, efficient and repeatable heat for a wide range of industrial applications.

An induction heating system designed for fast, clean, and safe removal of paint and industrial coatings, reducing stripping time by