Induction Brazing System

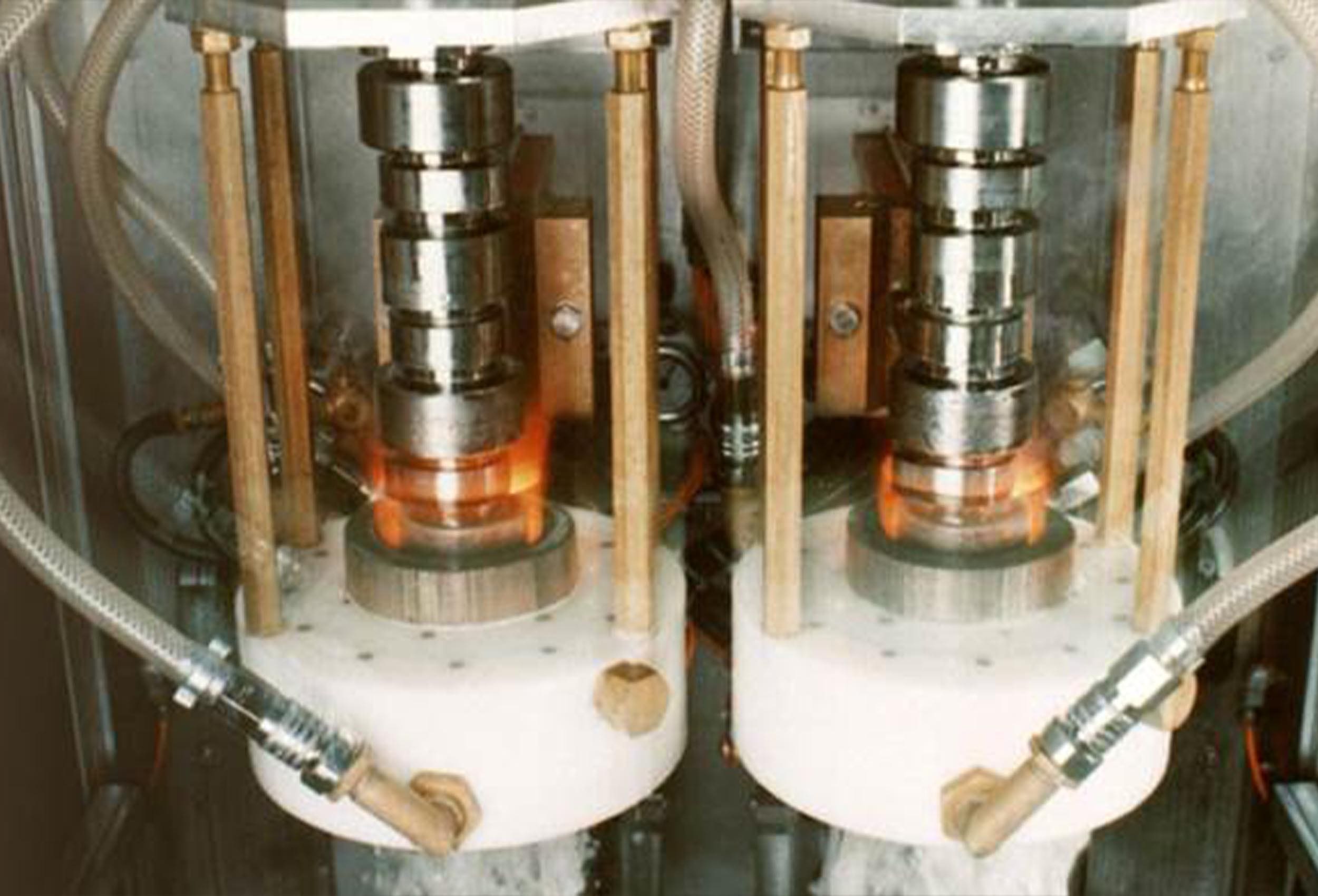

A comprehensive induction brazing technology offering fast, precise, clean and repeatable joining for a wide range of metals and industrial

HardLine is ENRX Induction’s family of advanced industrial heat treatment systems designed for both surface and through hardening applications. The range includes vertical machines, horizontal centerless systems, rotary table solutions, and fully customized hardening installations. These systems cover a wide variety of components such as gears, camshafts, crankshafts, drive shafts, torsion bars, couplings, rock drills, brake discs, CV joints, shock absorbers, bearings, and many more.

All HardLine machines are powered by ENRX high-efficiency SINAC frequency converters, delivering optimal hardening results and process stability. The systems are engineered for seamless in-line integration, reduced footprint, fast setup, minimal downtime, and high-speed hardening through advanced motion controls, IoT-based diagnostics, and precise metallurgical outcomes.

Custom-engineered systems are a major part of the HardLine offering—ENRX provides specialized laser hardening, drum (Trunnion) systems, and multi-zone hardening/tempering solutions, along with comprehensive global service, simulation support, operator training, and preventive maintenance programs.

Industrial induction hardening of a wide range of components, including:

Suitable for small to large-scale mass production environments.

Systems are designed to meet industrial safety and quality standards.

A comprehensive induction brazing technology offering fast, precise, clean and repeatable joining for a wide range of metals and industrial

A new-generation modular vertical induction hardening system offering maximum flexibility, Industry 4.0 readiness, and suitability for a wide range of

An in-line induction hardening and tempering system designed to produce premium-grade industrial chain with high speed, precision and consistency.

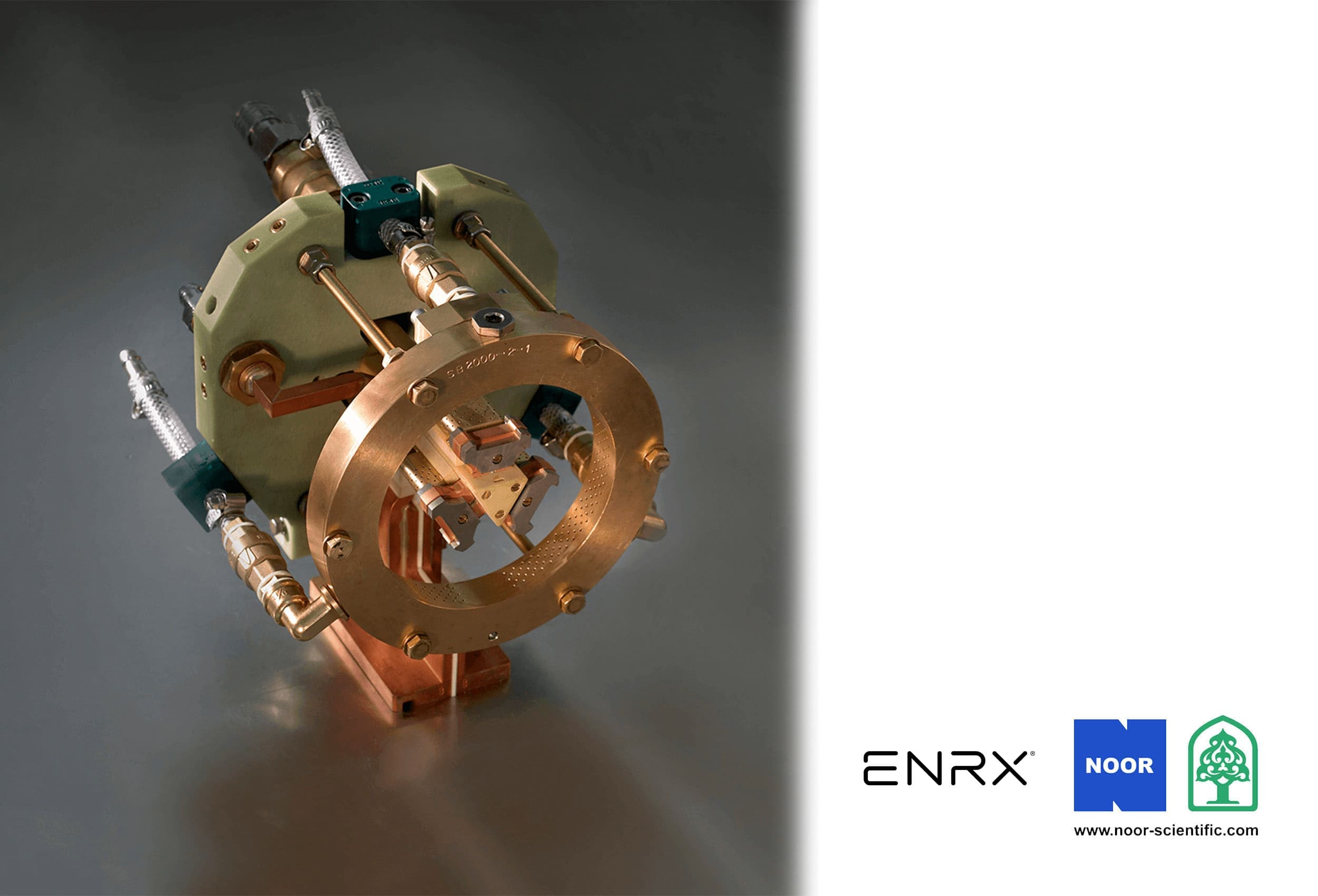

A high‑precision, flame‑free induction brazing solution designed to deliver efficient, repeatable and aesthetically clean brazed joints for faucet manufacturing.