HardLine – Vertical Heat Treatment Machines (VS / VM / VL / VXL)

A range of vertical induction heat treatment machines designed for small to very large components, featuring CNC control, modular design,

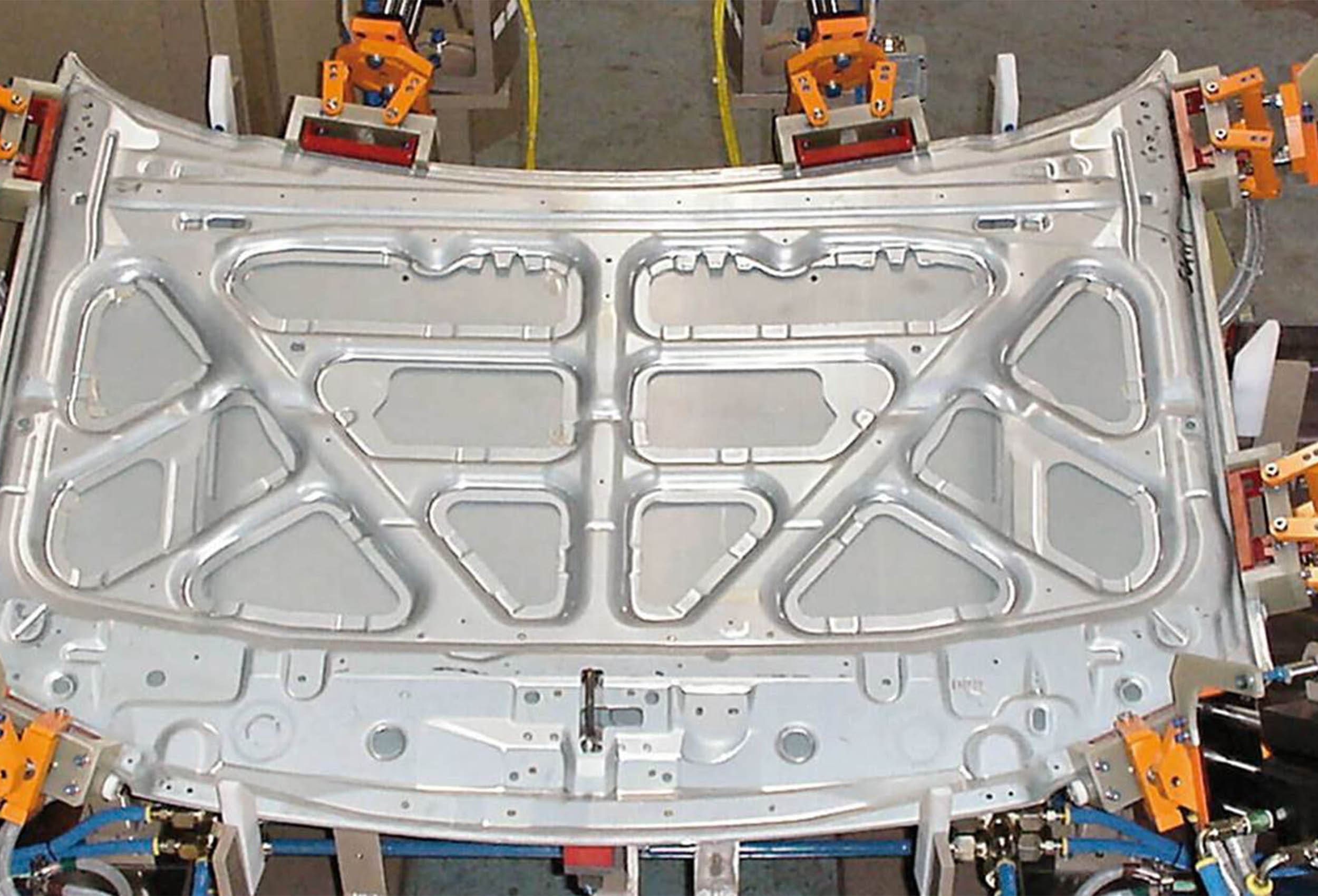

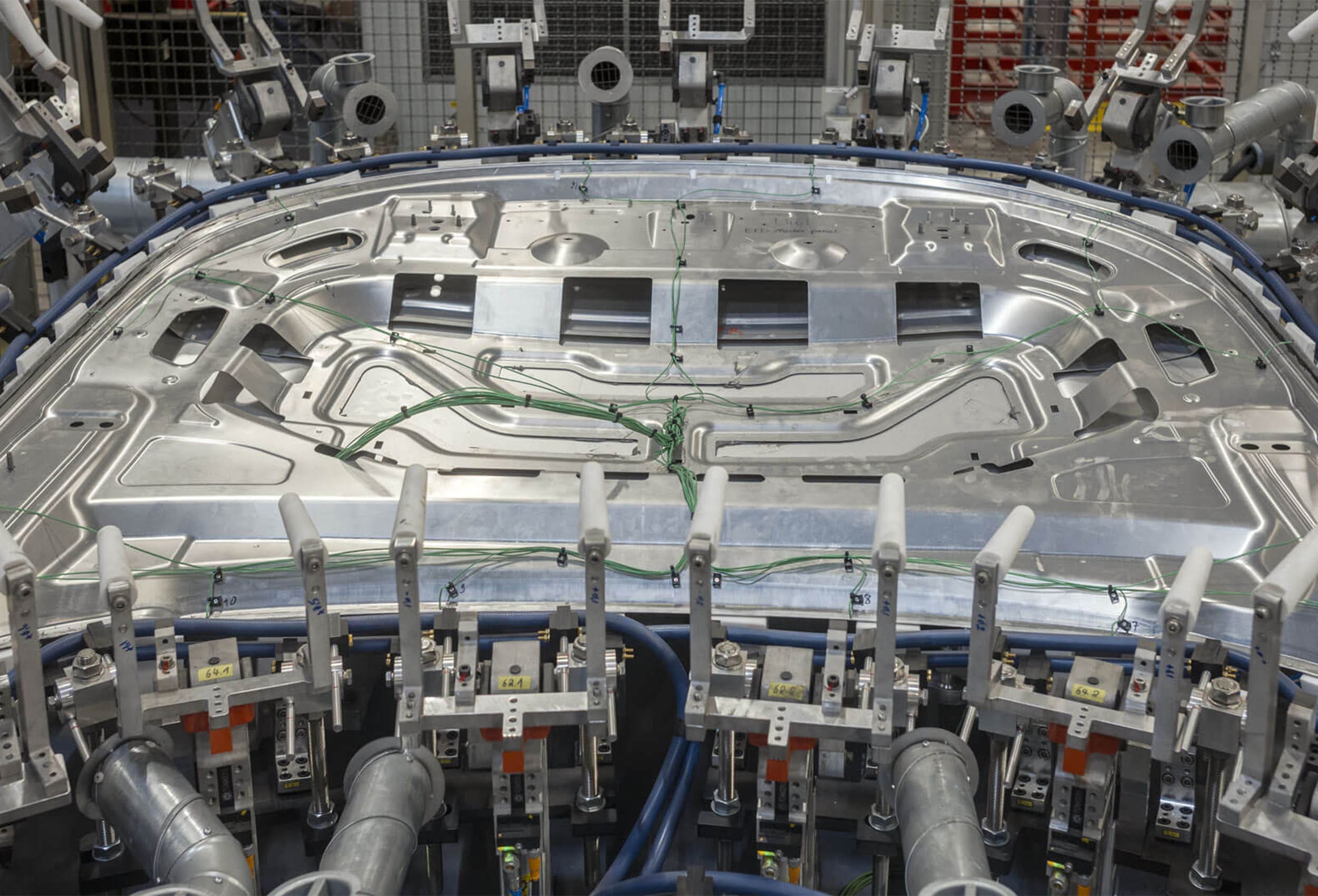

ENRX induction bonding systems use controlled induction heating to cure bonding adhesives and sealers for automotive components such as doors, hoods, fenders, tailgates, bumpers and battery modules. Induction bonding is the primary method used in the automotive industry due to its high throughput, excellent process control and compatibility with advanced materials including aluminium, steel, carbon-fiber composites and EV battery structures.

Two bonding methods are supported: spot-bonding using the U-coil, which heats localized areas with minimal distortion, and full-ring bonding using an adjustable two-turn flexible coil that ensures uniform heating around the entire joint. Temperature is rapidly ramped and then stabilized to meet adhesive curing profiles. Energy supervision circuits ensure consistent quality and detect deviations in coil placement or panel positioning.

Used extensively in automotive manufacturing for bonding:

Suitable for high-volume EV and ICE vehicle assembly lines.

A range of vertical induction heat treatment machines designed for small to very large components, featuring CNC control, modular design,

An induction heating system designed for fast, clean, and safe removal of paint and industrial coatings, reducing stripping time by

A compact, portable, air‑cooled induction heating system designed for preheating, post‑weld heat treatment, and maintenance applications in shrink-fitting and demanding

A new-generation modular vertical induction hardening system offering maximum flexibility, Industry 4.0 readiness, and suitability for a wide range of