Induction Brazing System

A comprehensive induction brazing technology offering fast, precise, clean and repeatable joining for a wide range of metals and industrial

ENRX faucet brazing systems offer a fast, controllable and highly repeatable heating method ideal for tube-to-socket, tube-to-tube and thread insert brazing. Induction provides localized, evenly distributed heat within predefined heating zones, allowing operators to achieve strong, full-penetration joints with minimal risk of overheating, porosity or weak bonding. Custom-designed inductors ensure compatibility with specific faucet geometries, while process parameters—such as temperature, ramp-up and dwell time—can be fully pre-programmed. The technology is quiet, clean, flame-free and ideal for robotic handling and in-line production environments.

Induction brazing of faucets including:

Used extensively in high-volume faucet manufacturing requiring clean, strong, corrosion-resistant joints and visually premium finished products.

A comprehensive induction brazing technology offering fast, precise, clean and repeatable joining for a wide range of metals and industrial

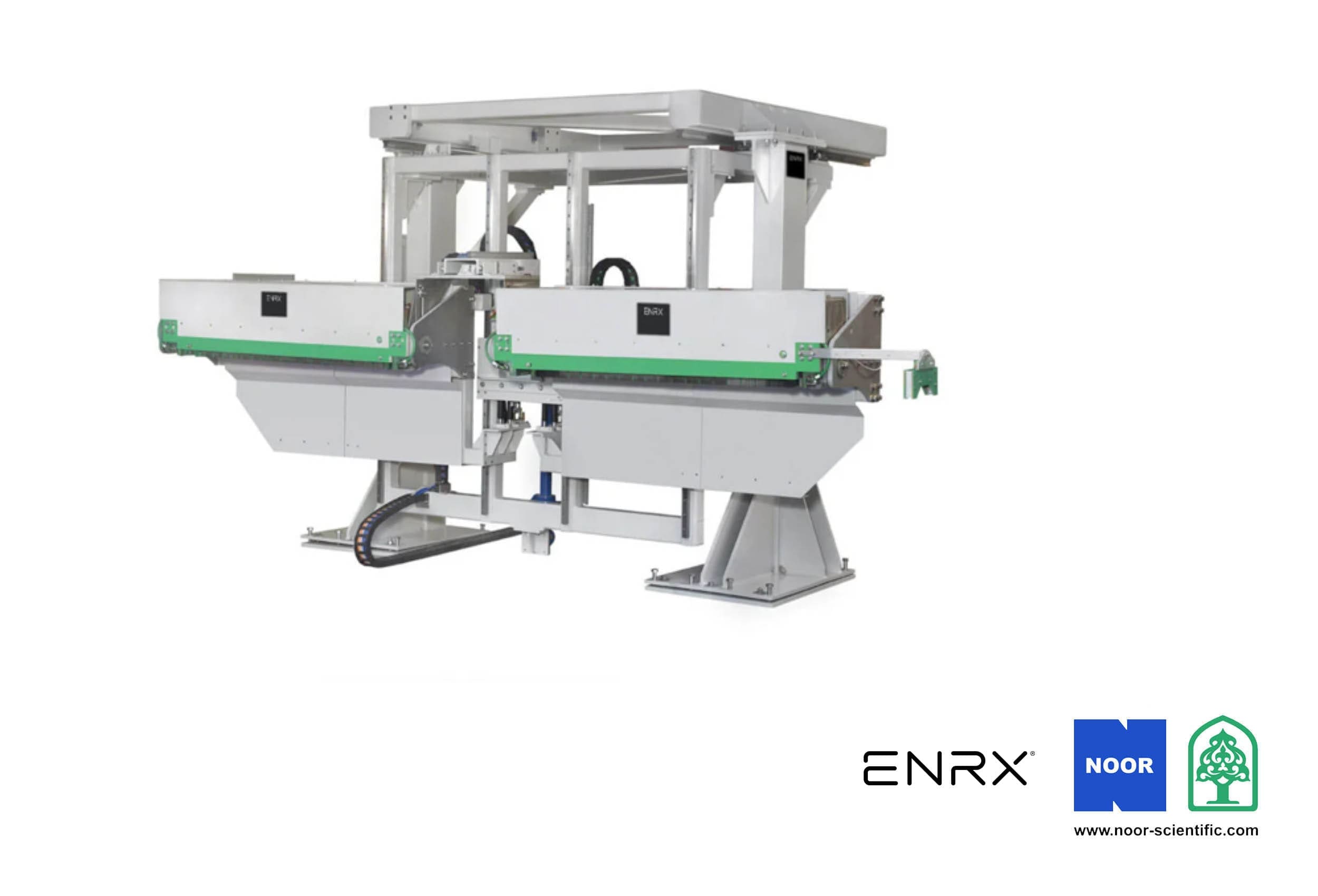

Induction-based seam normalizing systems designed for longitudinally welded pipes, providing precise, controllable and efficient heat treatment for oil and gas

A fully digital, mobile, flexible induction heating system equipped for Industry 4.0, offering precise, efficient heating for a wide range

A complete family of high‑output solid‑state induction welders for tube and pipe production, delivering high efficiency, compact design, and minimal