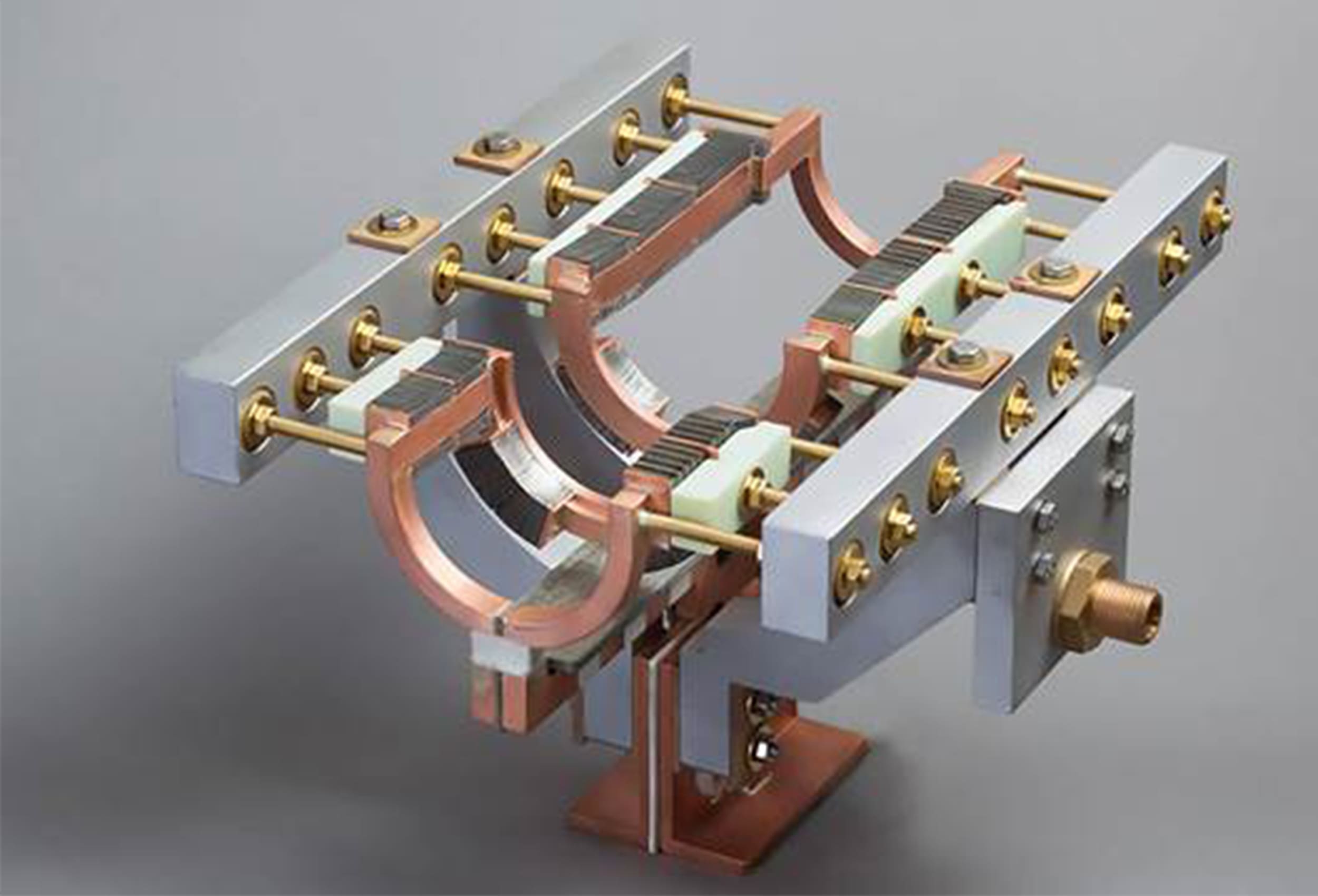

Induction Brazing System for Faucets

A high‑precision, flame‑free induction brazing solution designed to deliver efficient, repeatable and aesthetically clean brazed joints for faucet manufacturing.

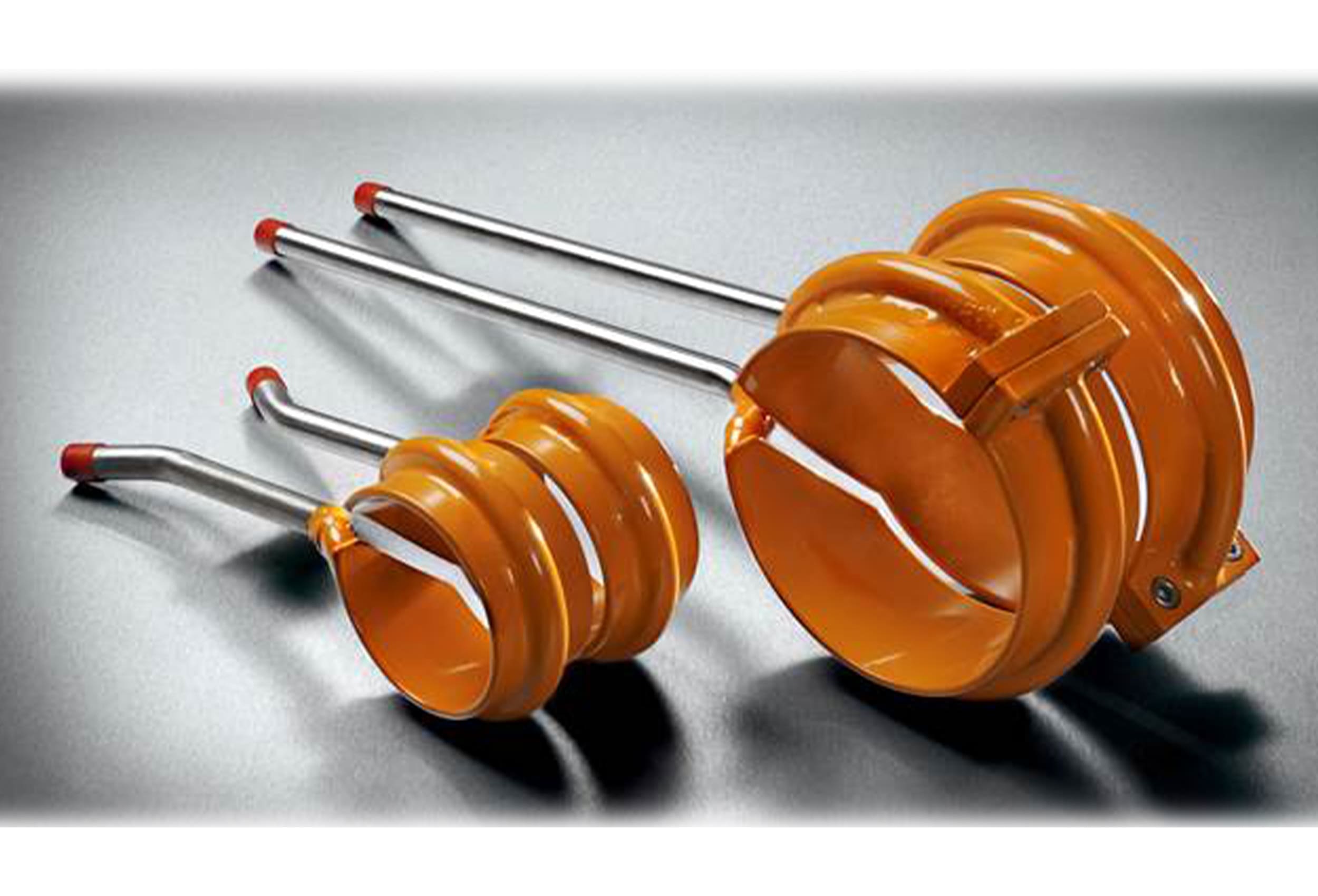

ENRX induction coils are the core component of any induction heating system, designed to maximize heating efficiency, energy performance and process reliability. They are engineered based on detailed analysis of the customer’s application, material, heating pattern, temperature requirements and power source. ENRX offers four main coil categories — Conventional, Machined, 3D-printed and Hybrid coils — allowing optimized solutions for brazing, soldering, hardening, forming, and other heating operations.

Each coil undergoes a structured development process including planning, 3D designs, simulation, real-life testing and final inspection. All coil data is stored in ENRX’s database, ensuring perfect reproducibility, repairability and replacement when needed. ENRX also supports customers with consultation, maintenance, installation, commissioning and coil reconditioning.

Induction coils are used across industries for processes including:

Coils are suitable for both manual and fully automated induction heating systems.

Manufactured in ENRX ISO-9001 certified production facilities with full documentation and traceability.

A high‑precision, flame‑free induction brazing solution designed to deliver efficient, repeatable and aesthetically clean brazed joints for faucet manufacturing.

A complete family of high‑output solid‑state induction welders for tube and pipe production, delivering high efficiency, compact design, and minimal

Advanced induction heating solutions for maintenance, repair and manufacturing operations across the railway industry.

An induction-based system for fast, safe and precise expansion of bolts used in turbines and heavy-duty assemblies.