Induction Brazing System for Faucets

A high‑precision, flame‑free induction brazing solution designed to deliver efficient, repeatable and aesthetically clean brazed joints for faucet manufacturing.

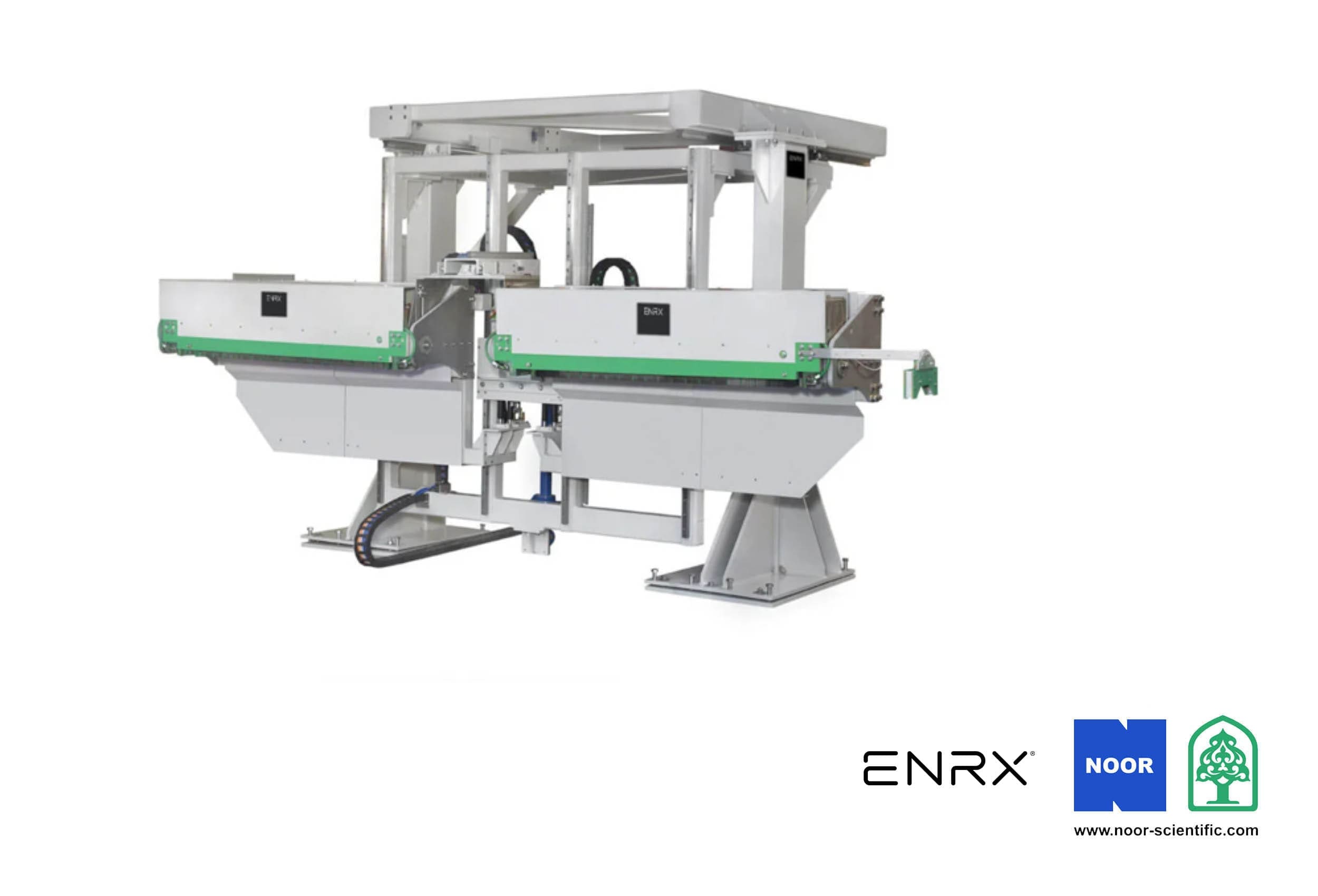

ENRX seam normalizing systems provide highly accurate, reliable and controllable heat treatment for longitudinally welded pipes. new generations of high-yield, thermo-mechanically processed steels require extremely precise heating profiles. ENRX addresses these challenges with advanced simulation modeling and optimized coil design that deliver accurate alloy- and gauge-specific heating and cooling zones.

The systems integrate easily into existing or new welding lines and are engineered to minimize installation length thanks to efficient air-cooling and optimized coil geometry. ENRX provides NQN and NQT technologies for full inner-wall homogenization, controlled heat-affected-zone (HAZ) coverage, and minimal outer-wall overheating.

Control systems—designed specifically for Induction—ensure precise temperature control, seam tracking using horizontal, orbital or travelling coil systems, and independent control of up to four heating stations. Advanced simulation tools (page 3) ensure optimized heat patterns across the pipe wall.

The systems are designed for compliance with oil and gas industry seam-normalizing standards and supported by advanced MES-compatible control software.

A high‑precision, flame‑free induction brazing solution designed to deliver efficient, repeatable and aesthetically clean brazed joints for faucet manufacturing.

An in-line induction hardening and tempering system designed to produce premium-grade industrial chain with high speed, precision and consistency.

A new-generation modular vertical induction hardening system offering maximum flexibility, Industry 4.0 readiness, and suitability for a wide range of

Induction-based seam normalizing systems designed for longitudinally welded pipes, providing precise, controllable and efficient heat treatment for oil and gas