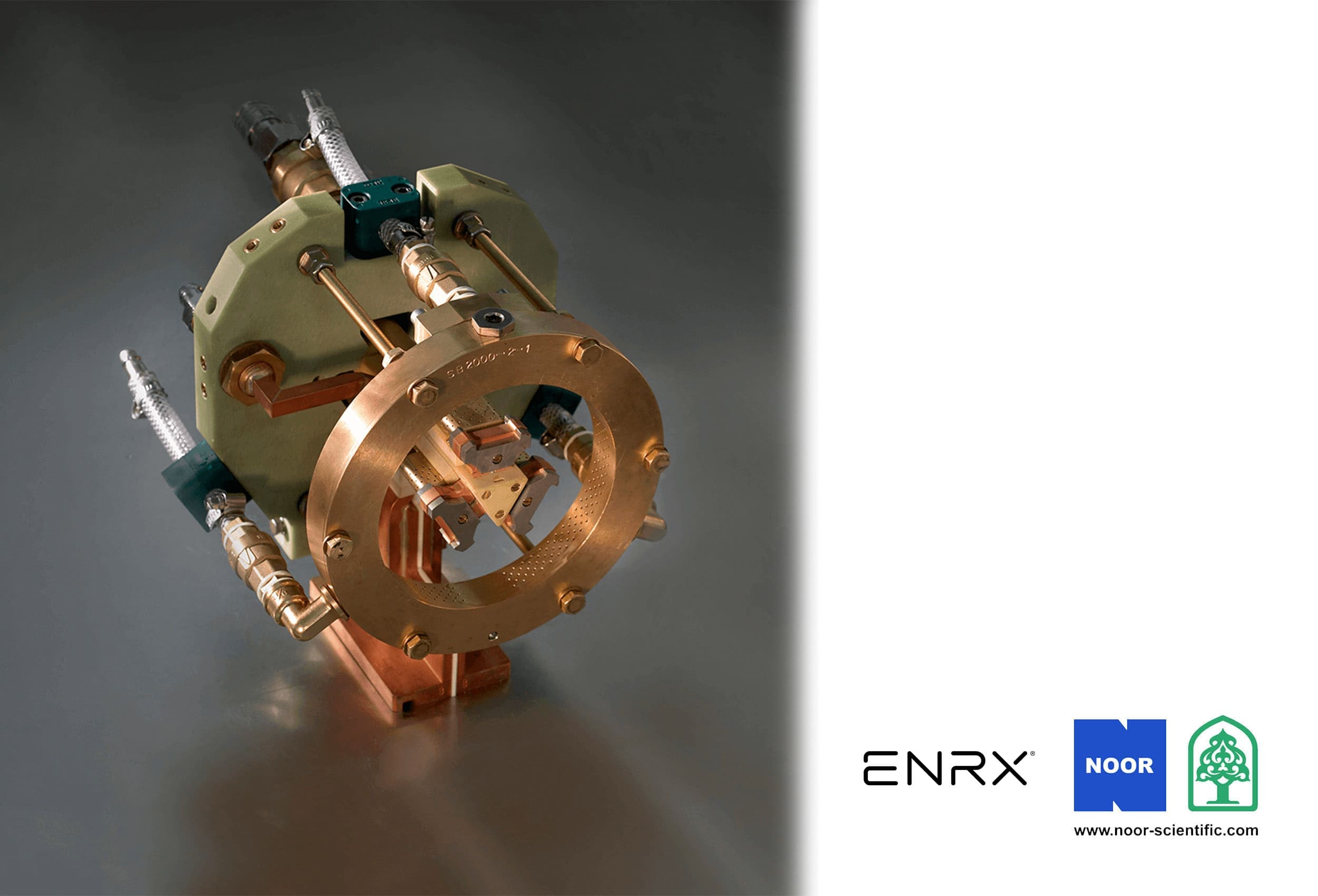

Induction Bonding System

A high‑precision induction bonding system used for curing adhesives and sealants in automotive aluminium and steel panel assemblies.

Induction heating is the preferred method for mounting bearings, rotors, impellers and pump components. Technology provides fast, clean and controlled heating that expands metal parts to allow easy assembly without mechanical stress or overheating.

The system delivers uniform through-heating, reducing risk of distortion, burns, or damage to precision-machined surfaces. Induction avoids open flames and contact heating, offering predictable temperature rise with full control over heating cycles, holding temperatures and ramp-up speeds.

The shrink-fitting process is compatible with a wide range of motor housings, shafts, rings and pump assemblies. Mobile Minac units or stationary Sinac systems can be used depending on workshop layout and production volume.

Systems conform to industrial electrical and safety standards.

A high‑precision induction bonding system used for curing adhesives and sealants in automotive aluminium and steel panel assemblies.

A range of vertical induction heat treatment machines designed for small to very large components, featuring CNC control, modular design,

A new-generation modular vertical induction hardening system offering maximum flexibility, Industry 4.0 readiness, and suitability for a wide range of

An induction heating system designed for fast, clean, and safe removal of paint and industrial coatings, reducing stripping time by