Induction Bonding System

A high‑precision induction bonding system used for curing adhesives and sealants in automotive aluminium and steel panel assemblies.

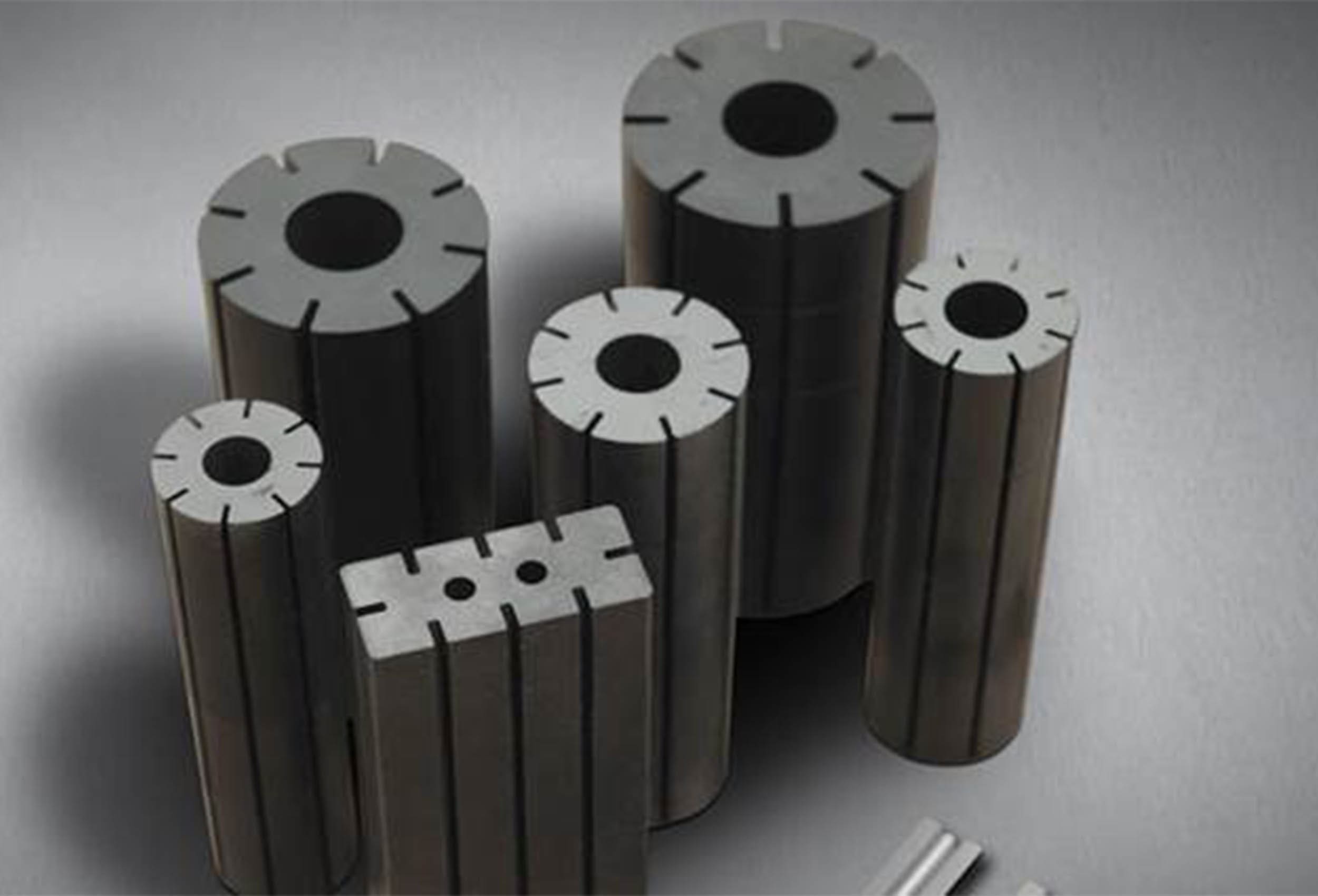

ENRX Tube Welding Consumables provide a complete portfolio of advanced components engineered to optimize welding efficiency, reduce energy consumption, and increase production reliability in HF tube and pipe mills. The product range includes through-flow impeders, return-flow impeders, hollow impeders, impeder clusters, rectangular impeder systems, ferrite cores, induction welding coils, scarfing systems, impeder support systems, couplings, and cooling accessories.

All impeders are designed using high-performance fluted ferrite formulations to minimize eddy current losses and maximize magnetic efficiency. Multiple casing technologies—Epoxy Glass, Ferroglass™, S300WG coatings—offer high-temperature stability, improved wear resistance, and extended service life. The range also includes specialized heavy-duty impeders for low-frequency and high-power welding lines.

Consumables also cover scarfing tools (internal and external), carbide inserts, Canticut ID systems, Duratrim edge scarfing, and complete cluster assemblies for large-diameter pipes. ENRX additionally offers a full range of proprietary ferrite grades (HR4B/HR5, Ferromax) optimized for HF welding.

All products are manufactured according to strict quality standards and delivered with full application support, engineering guidance, and global service coverage.

Used in high-frequency welding of:

Applications include: impeders, induction heating, scarfing, bead removal, tube forming optimization, and ferrite-based magnetic flux concentration.

ENRX consumables are produced under ISO-certified manufacturing processes with full traceability and quality documentation. Ferrite materials are developed to ENRX specifications by globally recognized producers.

A high‑precision induction bonding system used for curing adhesives and sealants in automotive aluminium and steel panel assemblies.

Induction heating system designed for fast, precise and safe shrink‑fitting of bearings, rotors, impellers, and pump components.

A comprehensive family of induction heat treatment systems for surface and through hardening, ranging from small manual units to large,

A high‑precision, flame‑free induction brazing solution designed to deliver efficient, repeatable and aesthetically clean brazed joints for faucet manufacturing.