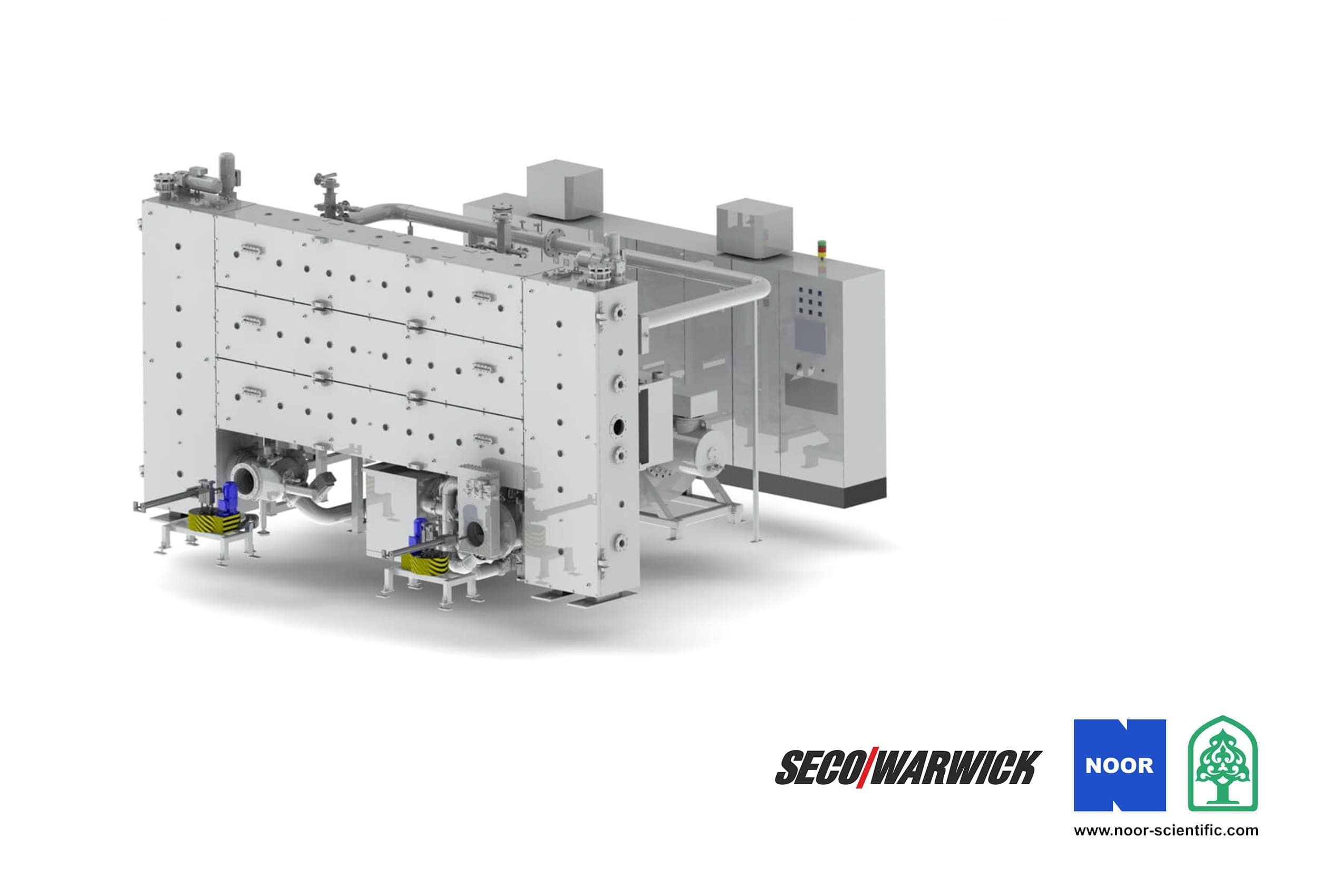

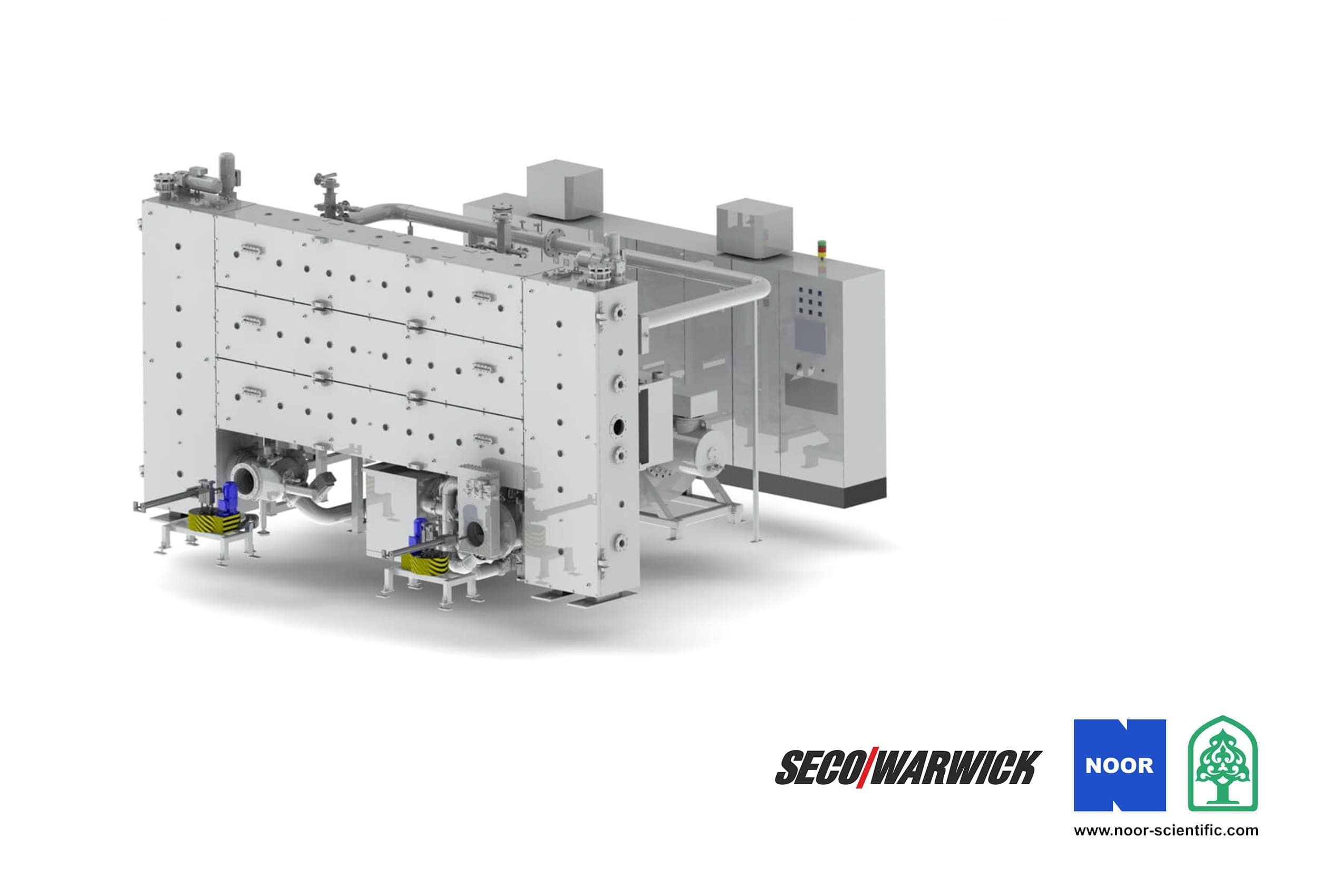

4D Quench® / UniCase Master – Single‑Piece Flow Vacuum Quenching System

A vacuum system for single‑piece nitrogen quenching with distortion control, offering an alternative to press quenching with high repeatability and

CVI furnaces are specialised systems used to produce carbon-based materials by infiltrating porous structures with carbon deposited from gaseous precursors. They ensure controlled layer formation and are used in high-performance industries requiring low weight, high temperature resistance, and excellent durability.

A vacuum system for single‑piece nitrogen quenching with distortion control, offering an alternative to press quenching with high repeatability and

Vacuum furnace system engineered for post‑processing of metal 3D‑printed parts, including debinding, sintering and heat‑treatment operations.

A vacuum-based aluminum coating technology providing corrosion‑resistant, conductive, and uniform metallic coatings for aerospace, defense, and high‑performance industrial components.

A family of flux‑free vacuum aluminum brazing furnaces including multi‑chamber continuous lines, batch tray systems, suspended‑load systems, and oil‑removal furnaces.