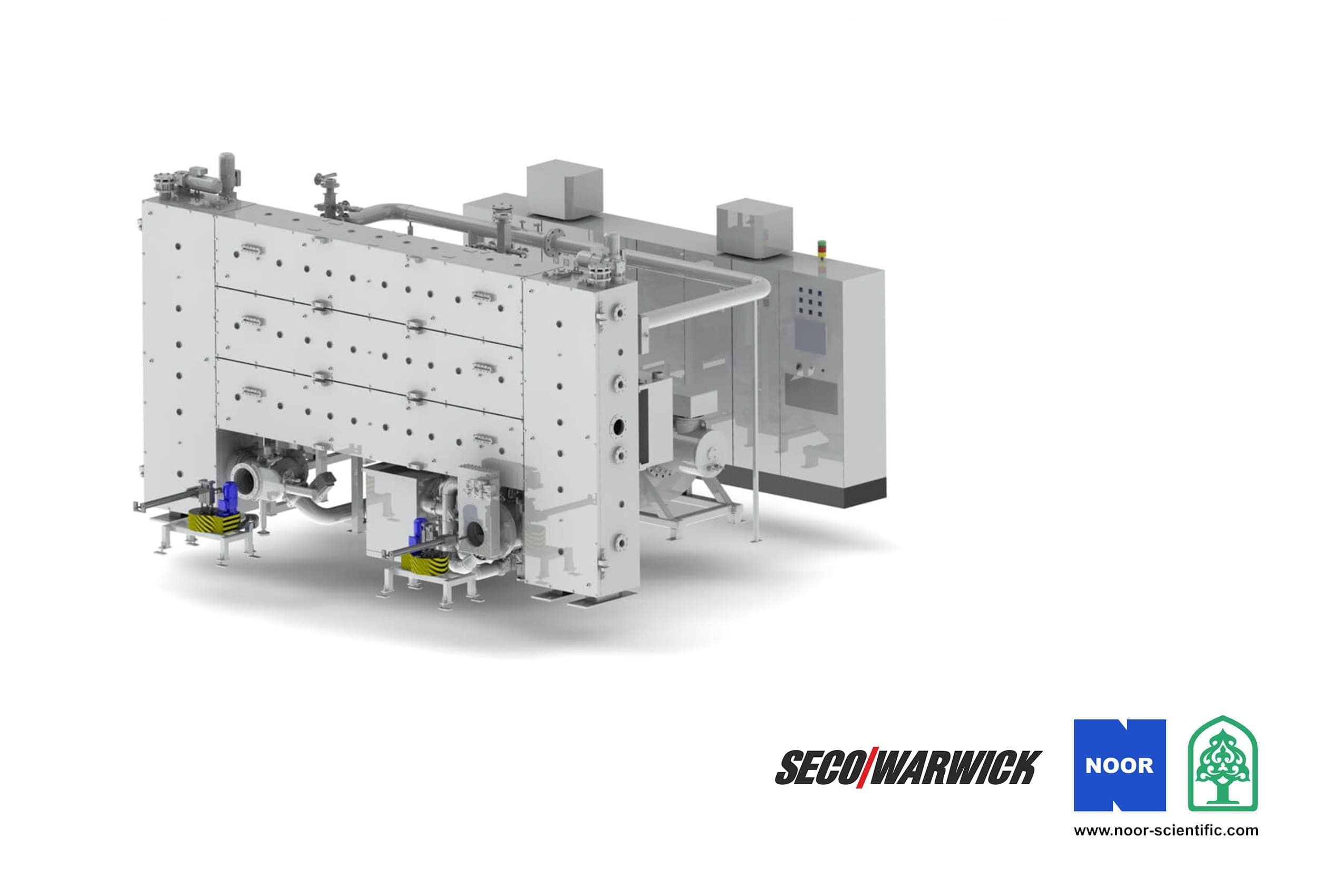

CaseMaster Evolution – T/D (Double & Triple Chamber Vacuum Furnace)

High‑efficiency double‑ and triple‑chamber vacuum furnaces designed for low‑pressure carburizing (LPC) and oil or gas quenching, providing high throughput, excellent

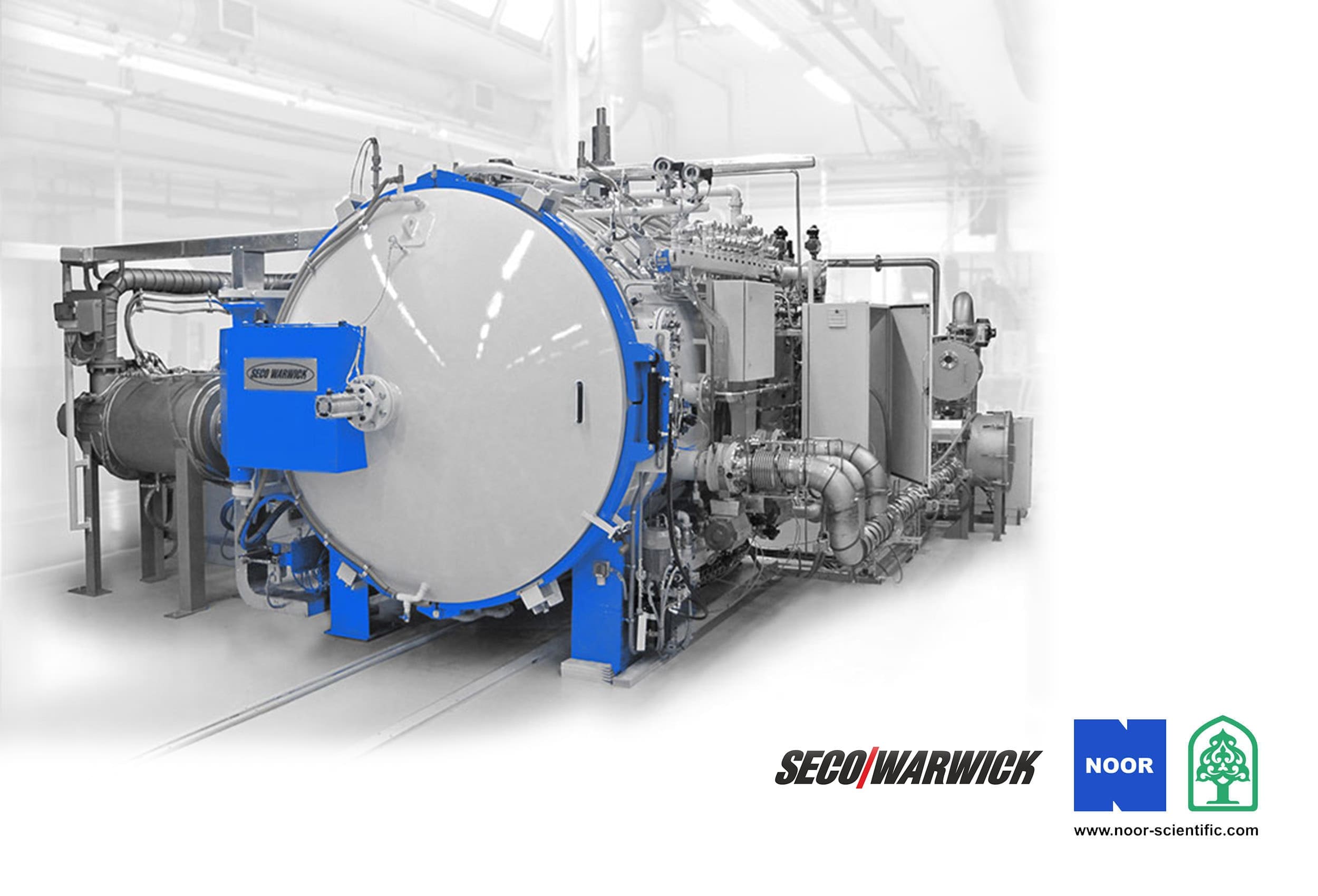

VECTOR HPGQ is a high-vacuum, single-chamber furnace engineered for precision heat-treatment applications requiring controlled, uniform and distortion-reduced quenching. The system integrates a high-pressure gas-quench module (typically 10–25 bar) using nitrogen, argon or helium, enabling fast and uniform cooling for aerospace steels, tool steels and other high-alloy components. The furnace offers a graphite or all-metal hot zone, multi-zone temperature control, convection heating enhancement and options for low-pressure carburizing and nitriding. It is designed for full compliance with demanding industrial and aerospace heat-treatment specifications and provides clean, oxidation-free vacuum processing with high repeatability from batch to batch.

Designed for compliance with industrial vacuum heat-treatment standards and AMS 2750; suitable for use in NADCAP heat-treating environments where required.

High‑efficiency double‑ and triple‑chamber vacuum furnaces designed for low‑pressure carburizing (LPC) and oil or gas quenching, providing high throughput, excellent

A vacuum system for single‑piece nitrogen quenching with distortion control, offering an alternative to press quenching with high repeatability and

Furnaces designed for controlled material coating deposition via gas‑phase chemical reactions.

Vacuum furnace system engineered for post‑processing of metal 3D‑printed parts, including debinding, sintering and heat‑treatment operations.