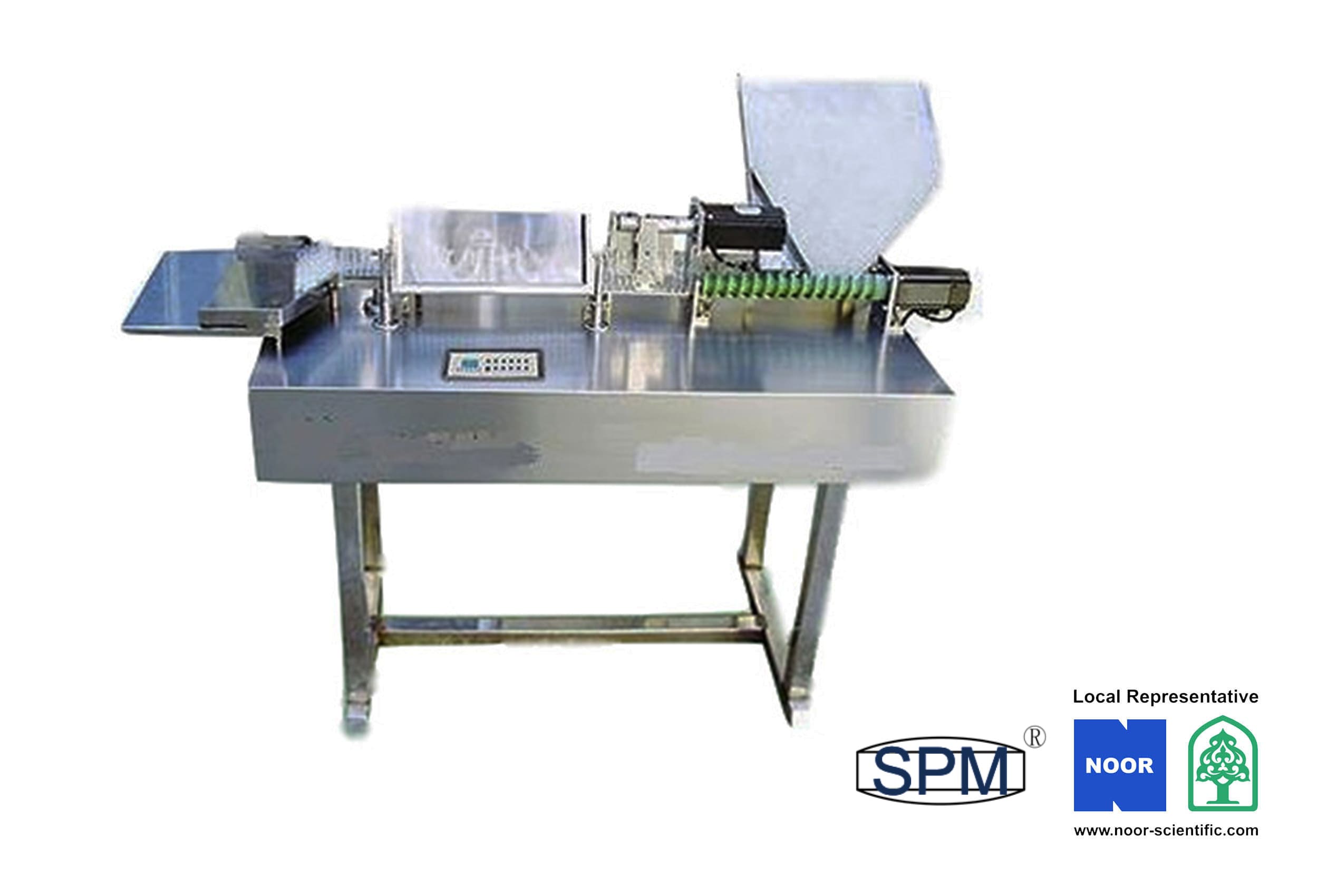

Eye Drop Production Line

Description

- Production Capacity: (10ml as standard)5800-6000(bts/Hr)

- Touch panel: SIEMENS, Japan HAKKA

- Filling pump: Belgium NEOCERAM, UK WATSON

- Glass hood for laminar flow: Acrylic glass or tempered glass

- HEPA filter: Sweden CAMFIL, USA AAF

- Bearing: SKF, Japan SEKIO& Motor: ABB, Japan Oriental

- Bottle arranger: (LP1) & Washing machine: (KCQ20)

- Tunnel oven: (GMS-A) & Eye drop filling machine: (DSG2)

- Light inspection machine: (DJ100)

- Labeling machine: (LTB-A)

- Outer material is stainless steel, dull polished. The whole line is good in appearance, easy to clean. It complies with GMP regulations and can be suitable for several bottle specs.

- Filling Dosage Feature: no dripping, no forming and no spitting.

- Performance Feature: running is stable, noise is low, filling is precise, energy consumption is low, qualified product ratio is high.

- The whole line can single machine control or interlock control. Washing machine 3 water and 3 air ensure washing effect; tunnel oven high temperature ensure drying bottles; peristaltic filling pump ensure filling precision; cap-screwing machine ensure sealing effect; labeling machine pneumatic coding ensure labeling speed.

- Comply with GMP requirements. Contact part is made of SS316L, silicone rubber or PTFE material which is easy to clean and without contamination.

Other Products From SPM Co. Ltd