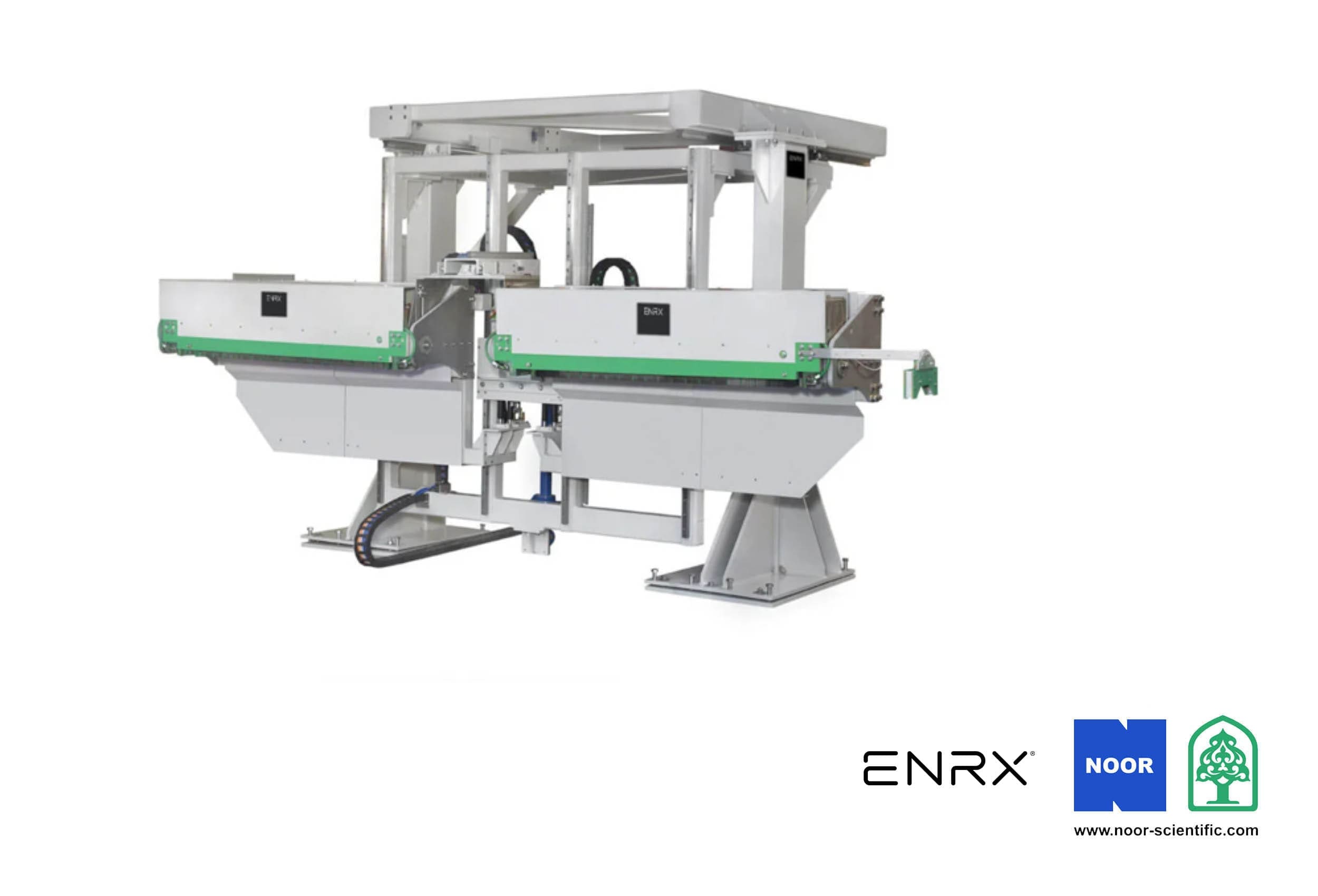

Sinac® – Stationary Induction Heating Systems

A stationary induction heating system delivering precise, contactless, efficient and repeatable heat for a wide range of industrial applications.

Induction heating is a fast, controlled and highly efficient method for expanding bolts in steam and gas turbines. A specially designed induction coil is inserted directly into the bolt, generating localized heat that expands the bolt by a precise predetermined amount, enabling easy removal of the nut without damaging the threads.

Because the heating process is extremely rapid, heat does not migrate to the thread area, preventing thread damage and eliminating the risk of rods melting inside the bolt—an issue often seen with resistance or flame heating. Operators can pre-set key parameters such as temperature, ramp-up time and dwell time, ensuring repeatable and consistent bolt expansion quality.

the Minac 25/40 Twin, which features two independent handheld transformers powered by one compact converter. This enables a single operator to heat two bolts simultaneously, effectively doubling productivity.

A stationary induction heating system delivering precise, contactless, efficient and repeatable heat for a wide range of industrial applications.

Induction-based seam normalizing systems designed for longitudinally welded pipes, providing precise, controllable and efficient heat treatment for oil and gas

A comprehensive range of high‑performance consumables for high‑frequency tube, pipe, and profile welding applications.

High‑efficiency in‑line induction heating systems for structural wires, cables, conductors, and optical fiber production.