Induction Bonding System

A high‑precision induction bonding system used for curing adhesives and sealants in automotive aluminium and steel panel assemblies.

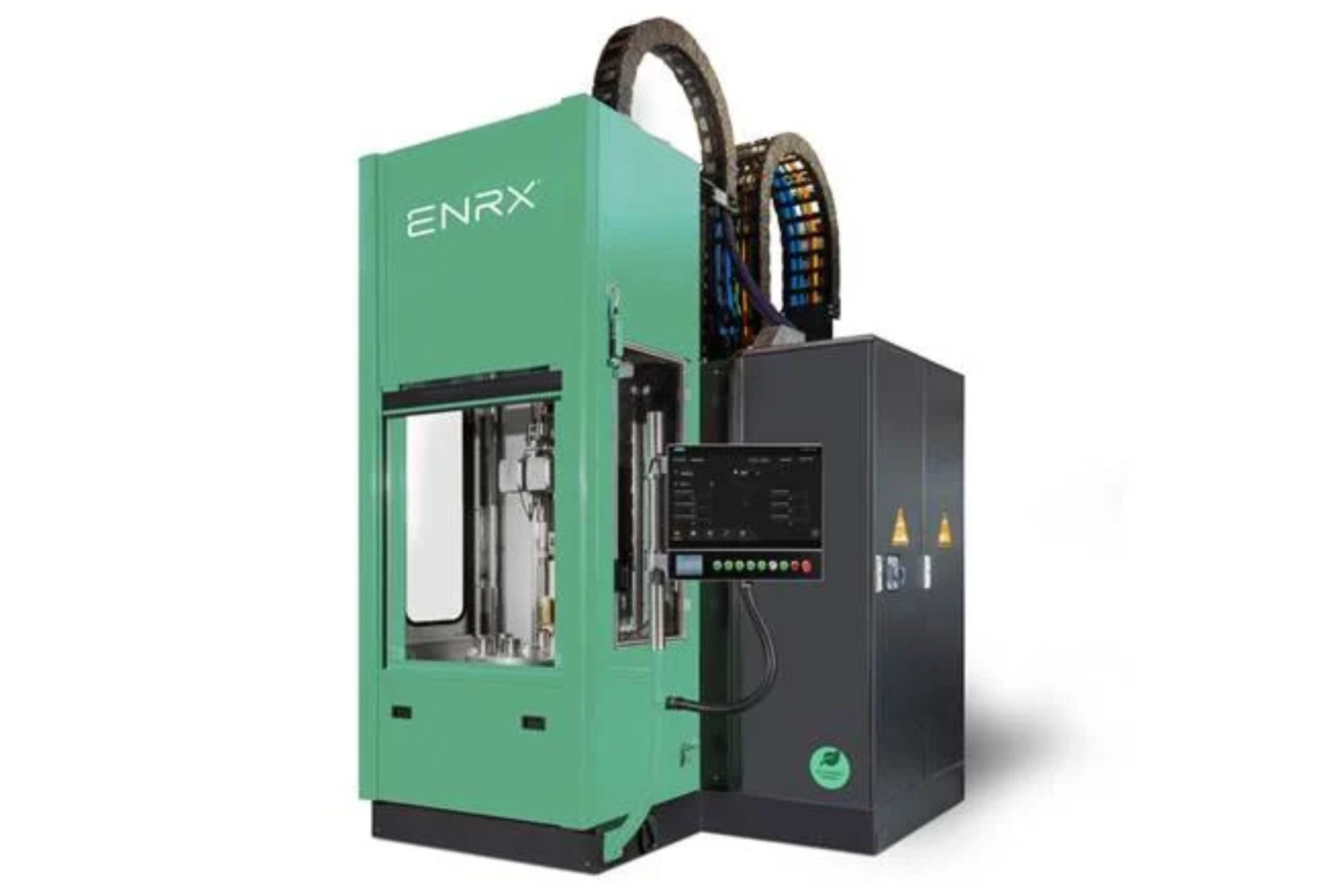

The HardLine M is a highly flexible modular vertical hardening machine designed for diverse hardening and tempering applications. It supports a wide range of workpiece sizes in weight, length, and diameter, making it ideal for both small-quantity jobs and heavy-duty components.

The HardLine M features advanced PLC-based machine control with real-time monitoring, remote diagnostics, and industry-leading data automation. It is built with high-quality modules ensuring long-term reliability, reduced maintenance requirements, and low operating costs. The machine is also future-ready, supporting Industry 4.0 with IoT connectivity, remote service, augmented reality troubleshooting, real-time data acquisition, and system digitization via optional extension modules.

Numerous machine configurations are available, including single/twin spindle, universal spindle, dual-station systems, and rotary table versions. The system can be used for both ramp-up manual loading and later upgraded to fully automated loading systems as production volumes increase.

Suitable for a wide range of induction hardening and tempering operations for components of various sizes. Applications include:

It is designed as an all-rounder for industries requiring flexible, scalable, and high-efficiency heat treatment systems.

The system is designed to meet modern industrial safety, automation, and performance standards.

A high‑precision induction bonding system used for curing adhesives and sealants in automotive aluminium and steel panel assemblies.

A complete family of high‑output solid‑state induction welders for tube and pipe production, delivering high efficiency, compact design, and minimal

Advanced induction heating solutions for maintenance, repair and manufacturing operations across the railway industry.

An induction heating system designed for fast, clean, and safe removal of paint and industrial coatings, reducing stripping time by