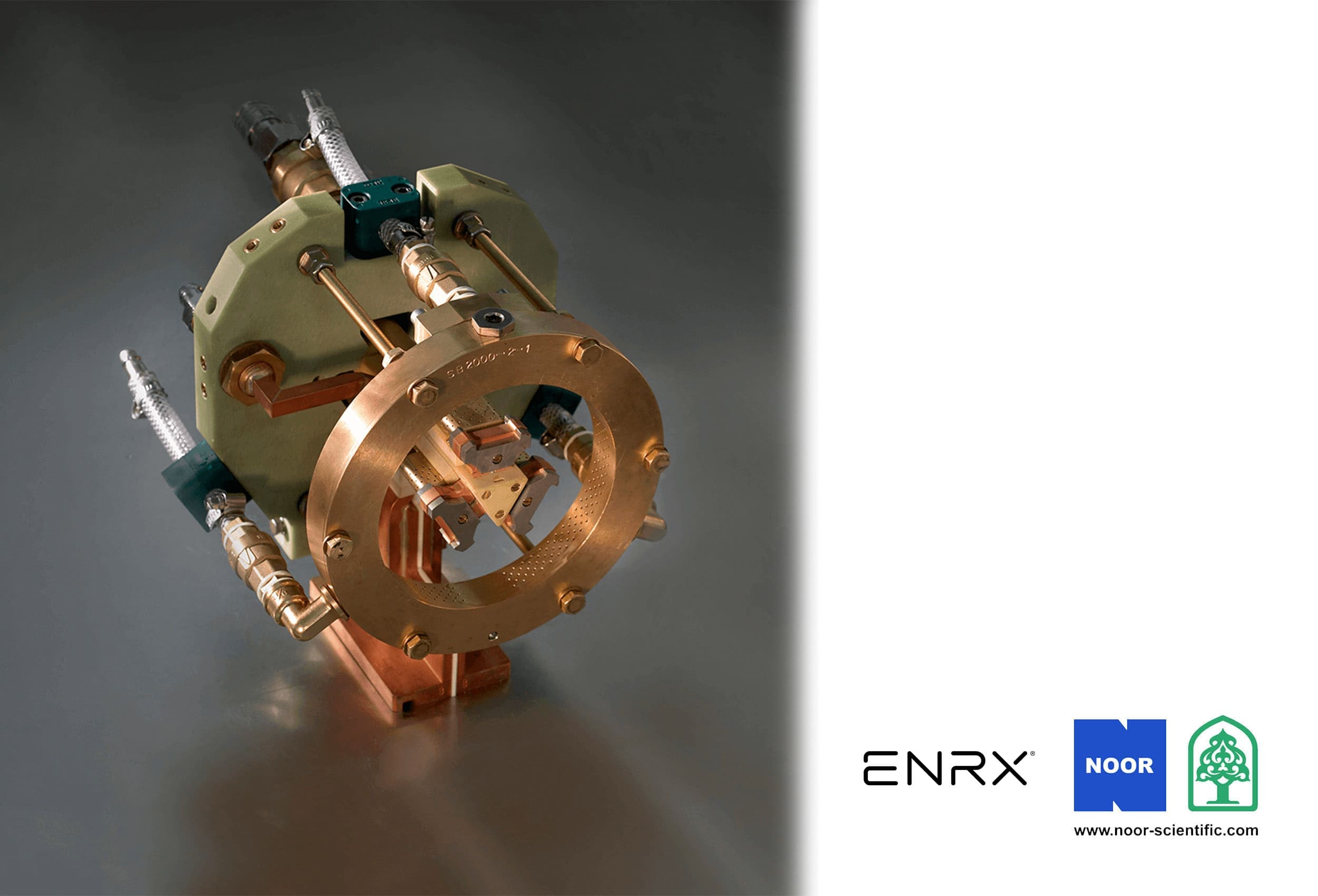

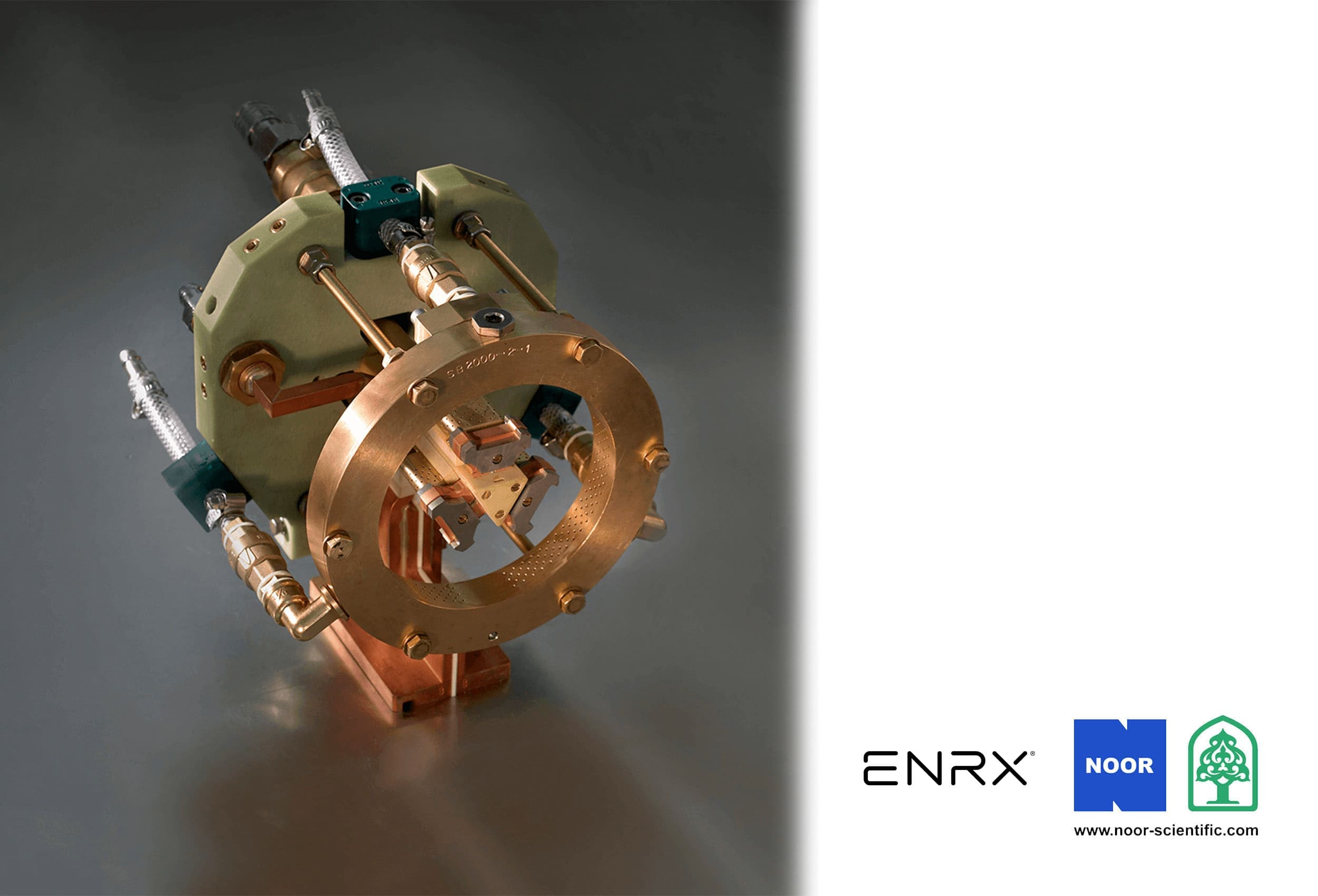

Induction Heating Coils

A new-generation modular vertical induction hardening system offering maximum flexibility, Industry 4.0 readiness, and suitability for a wide range of

HardLine vertical heat treatment machines by ENRX provide highly efficient, reliable, and automated induction hardening for a wide variety of workpieces. these systems reduce capital and operating costs thanks to their versatility, CNC precision, and advanced process control.

The machine types include:

All systems are powered by SINAC induction generators, available in serial or parallel compensated versions. Multi-frequency SINAC systems can deliver two frequencies simultaneously for optimal hardening of complex shapes .

As highlighted in the catalogue:

Induction hardening of numerous components including:

Suitable for automotive, heavy machinery, industrial equipment manufacturing.

systems are built to industrial safety and quality standards

A new-generation modular vertical induction hardening system offering maximum flexibility, Industry 4.0 readiness, and suitability for a wide range of

A range of vertical induction heat treatment machines designed for small to very large components, featuring CNC control, modular design,

A fully digital, mobile, flexible induction heating system equipped for Industry 4.0, offering precise, efficient heating for a wide range

Advanced induction heating solutions for maintenance, repair and manufacturing operations across the railway industry.