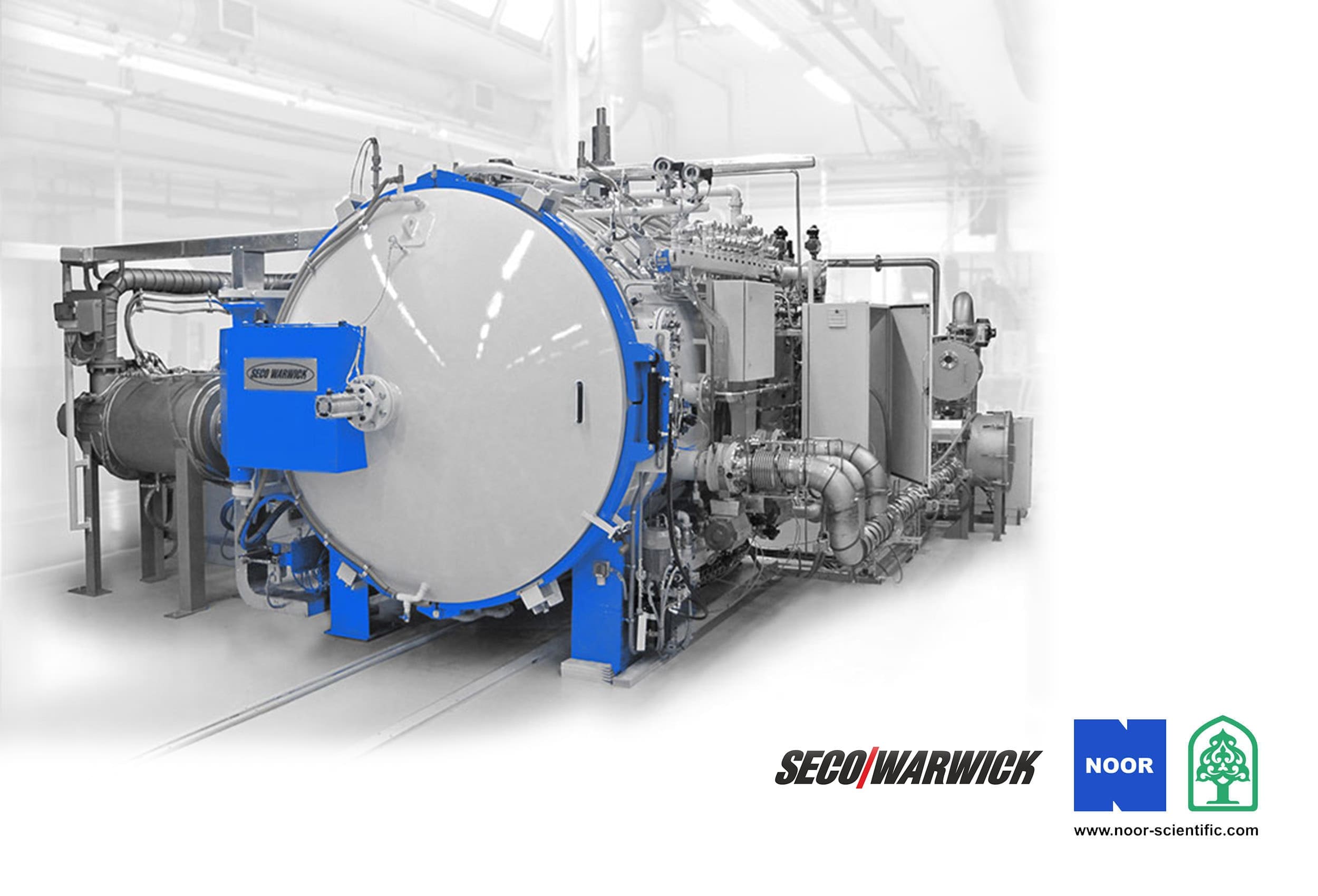

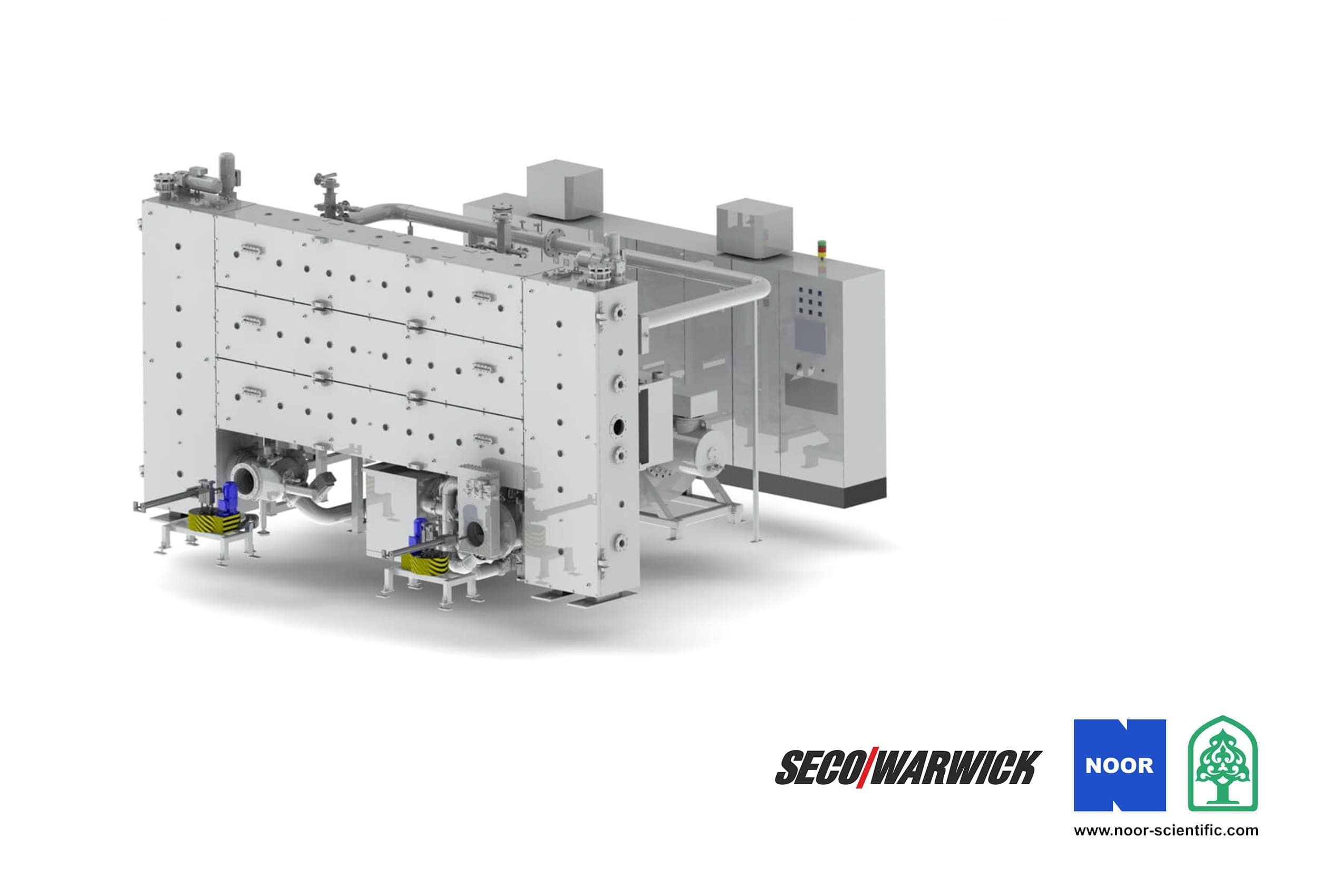

CaseMaster Evolution – T/D (Double & Triple Chamber Vacuum Furnace)

High‑efficiency double‑ and triple‑chamber vacuum furnaces designed for low‑pressure carburizing (LPC) and oil or gas quenching, providing high throughput, excellent

CaseMaster Evolution – T (CMe-T) is a triple-chamber horizontal vacuum furnace engineered specifically for high-volume low-pressure carburizing (LPC) and oil or high-pressure gas quenching. the system includes a dedicated pre-heating chamber, a process/heating chamber and a quenching chamber, enabling up to three loads to be processed simultaneously for maximum throughput.

The CMe-T design significantly shortens cycle times, reduces total operating cost and allows continuous or semi-continuous production. The system supports LPC, PreNit®, FineCarb®, oil quenching, 24-bar nitrogen or helium gas quenching and gas-over-oil modes. It provides oxidation-free processing, excellent case depth uniformity and very low distortion for demanding applications in automotive, aerospace and transmission industries.

Designed to comply with industrial vacuum heat-treatment standards and supports AMS 2750 and automotive heat-treat requirements.

High‑efficiency double‑ and triple‑chamber vacuum furnaces designed for low‑pressure carburizing (LPC) and oil or gas quenching, providing high throughput, excellent

Furnaces designed for controlled material coating deposition via gas‑phase chemical reactions.

A vacuum system for single‑piece nitrogen quenching with distortion control, offering an alternative to press quenching with high repeatability and

High‑vacuum single‑chamber furnace with gas cooling for advanced aerospace, energy, nuclear and high‑performance heat‑treatment applications.