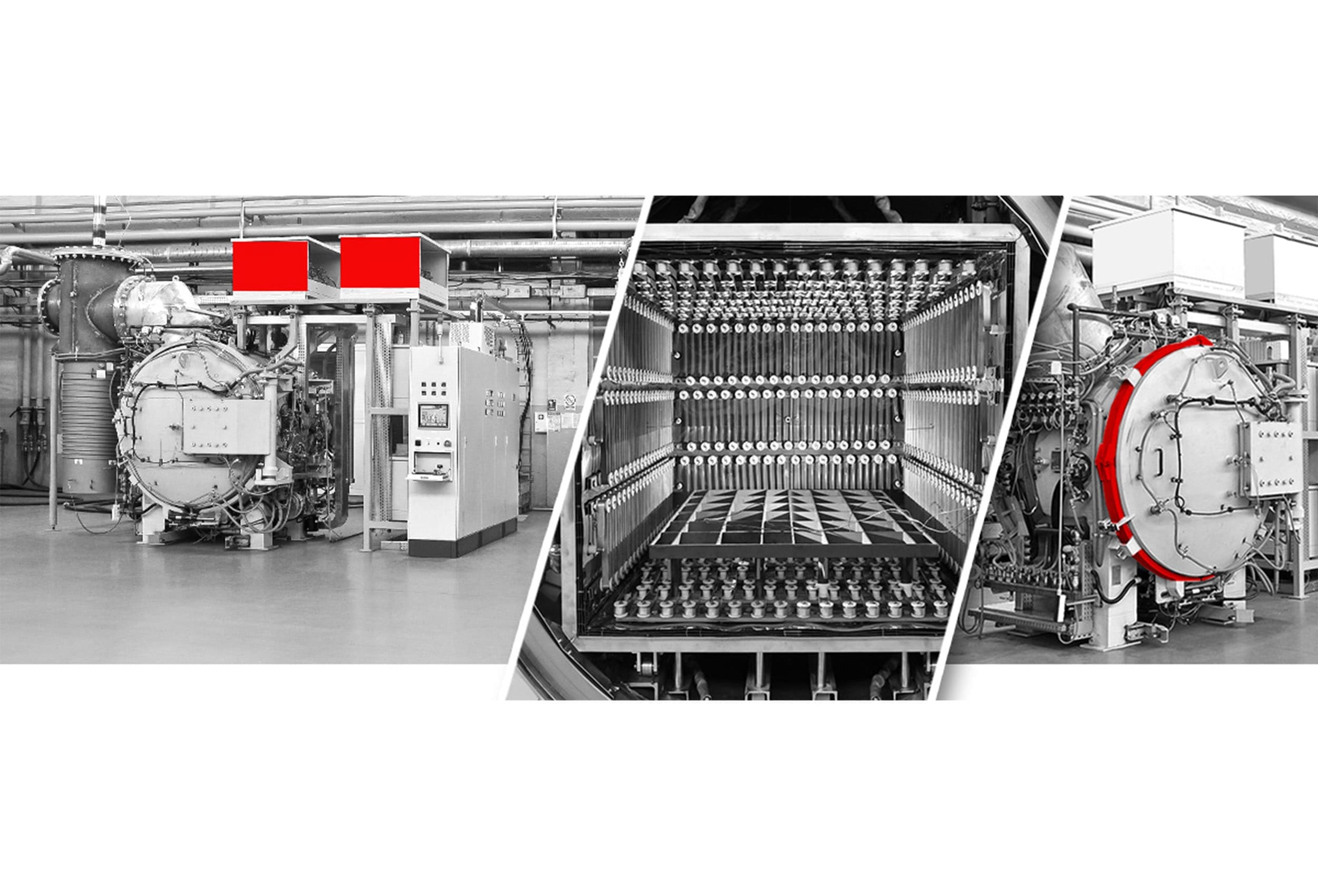

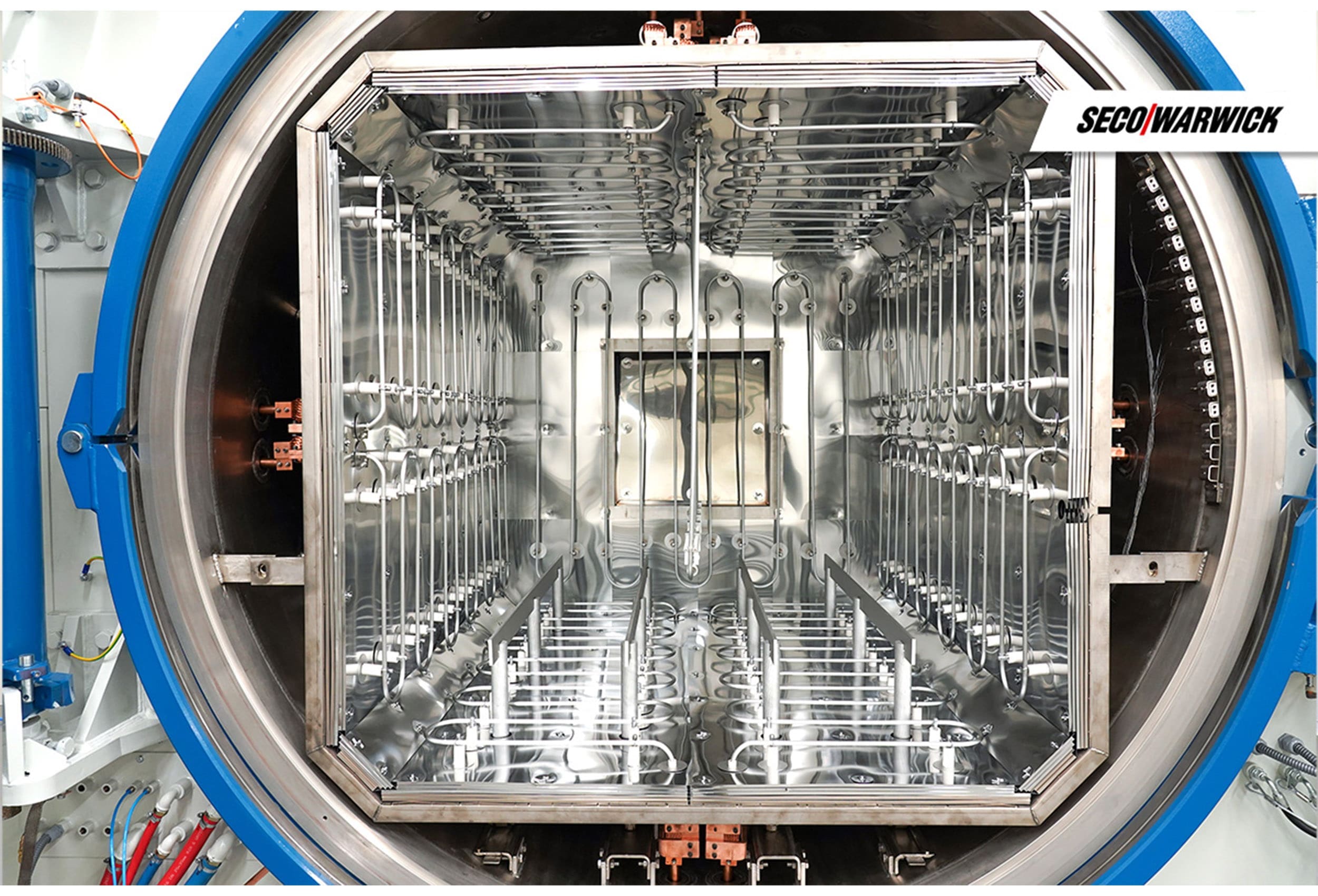

VAB Batch Chamber – Vacuum Aluminum Brazing Furnace

Batch‑type vacuum aluminum brazing furnace for suspended or tray‑loaded components using fluxless magnesium‑activated brazing.

Batch VAB furnaces are single- or dual-chamber vacuum aluminum brazing systems designed for high-quality, fluxless brazing of aluminum components. They are available in two main configurations: suspended-load furnaces with dedicated transport mechanisms, and tray-loaded batch furnaces for aerospace and commercial heat-treating applications. The system uses magnesium activation within a high-vacuum environment to remove oxides and moisture, ensuring uniform wetting and clean, oxide-free joints. Batch VAB furnaces provide stable vacuum conditions, multi-zone heating control and flexible loading options for complex assemblies.

designed to meet industrial vacuum aluminum brazing standards.

Batch‑type vacuum aluminum brazing furnace for suspended or tray‑loaded components using fluxless magnesium‑activated brazing.

Single-chamber horizontal vacuum furnace with high-pressure gas quenching, designed for a wide range of heat treatment processes with high uniformity,

Next‑generation carburizing furnace combining the benefits of traditional gas carburizing with vacuum‑quality cleanliness and low‑distortion quenching.

Vacuum furnace system engineered for post‑processing of metal 3D‑printed parts, including debinding, sintering and heat‑treatment operations.