Ion Vapor Deposition (IVD) Coating Furnaces

A vacuum-based aluminum coating technology providing corrosion‑resistant, conductive, and uniform metallic coatings for aerospace, defense, and high‑performance industrial components.

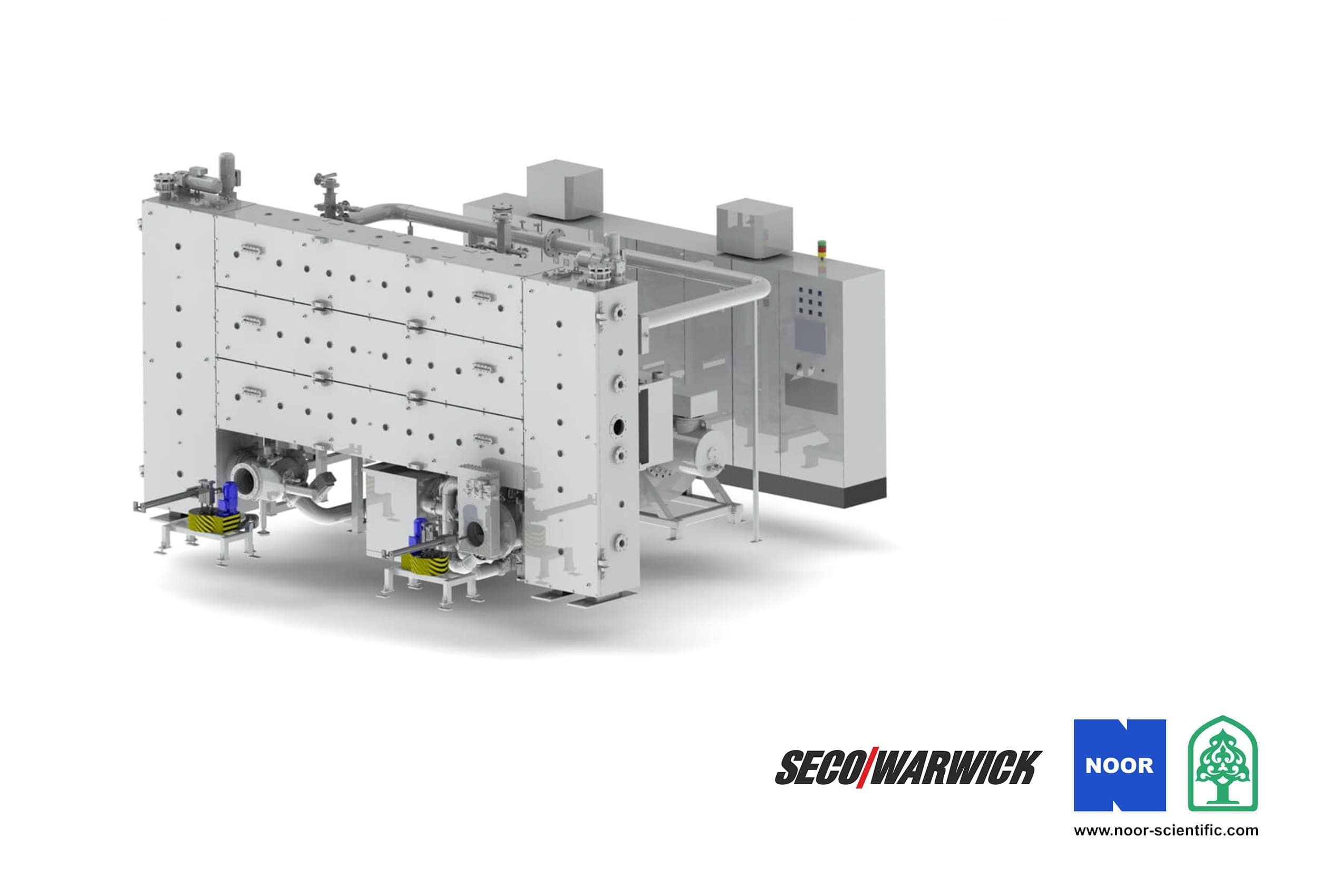

The VAB Line consists of multiple furnace configurations designed for vacuum aluminum brazing using fluxless technology. As shown in the catalogue, magnesium activation is used to remove oxygen and moisture, improving vacuum purity and allowing clean, uniform brazing of aluminum components. The line includes multi-chamber continuous systems for high-volume production, batch furnaces for aerospace and commercial processing, suspended-load systems for efficient heat distribution, and vacuum oil-removal furnaces for pre-cleaning before brazing. The technology supports complex shapes, multi-surface joints, and a wide range of aluminum alloys.

Designed to meet industrial vacuum brazing and aluminum-processing standards.

A vacuum-based aluminum coating technology providing corrosion‑resistant, conductive, and uniform metallic coatings for aerospace, defense, and high‑performance industrial components.

Single‑chamber vacuum furnace for precision nitriding and nitrocarburizing using ZeroFlow® atmosphere‑control technology.

Single-chamber high-vacuum furnace with high-pressure gas quenching (up to 25 bar), designed for distortion-controlled hardening of high-performance alloys and precision

A vacuum system for single‑piece nitrogen quenching with distortion control, offering an alternative to press quenching with high repeatability and