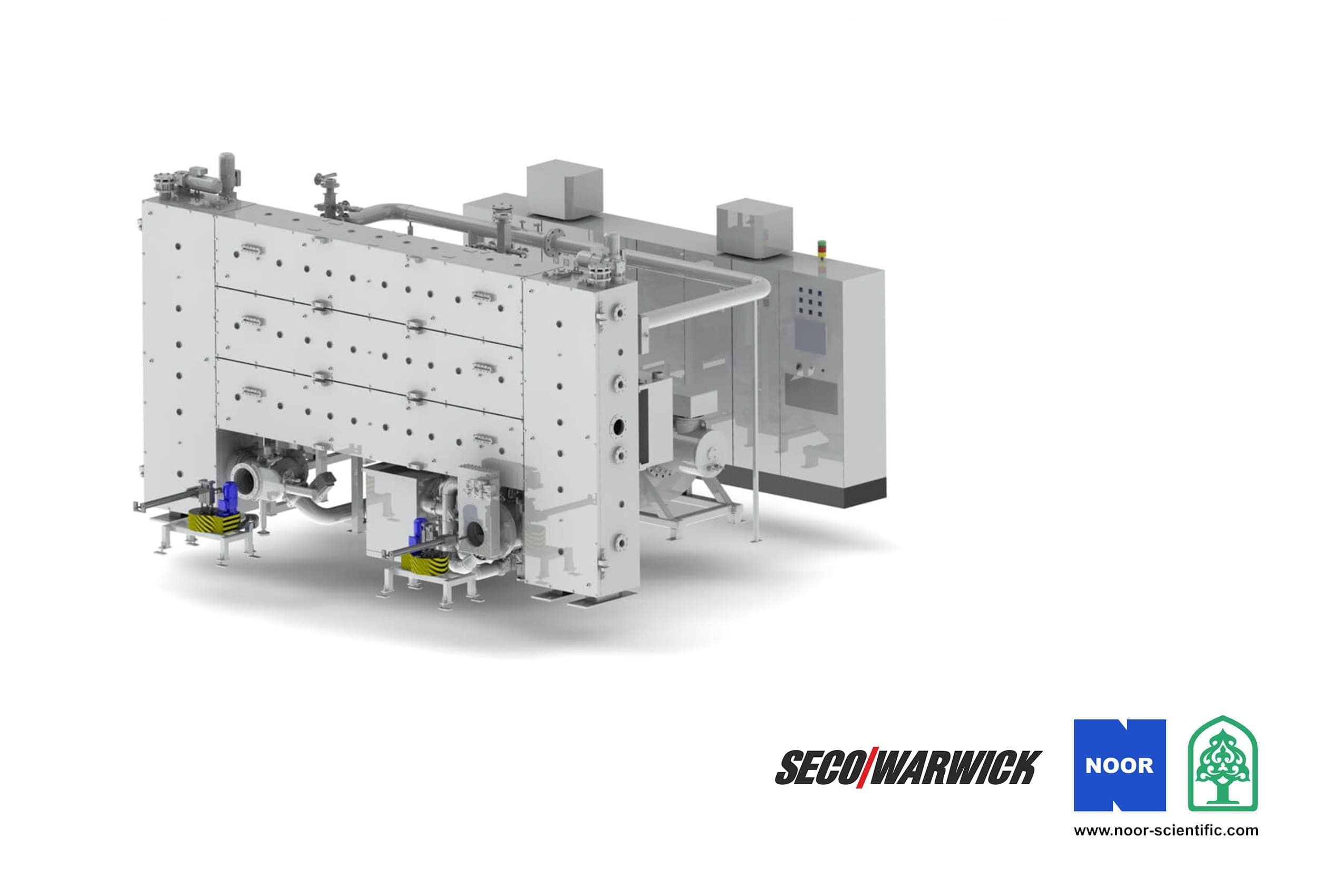

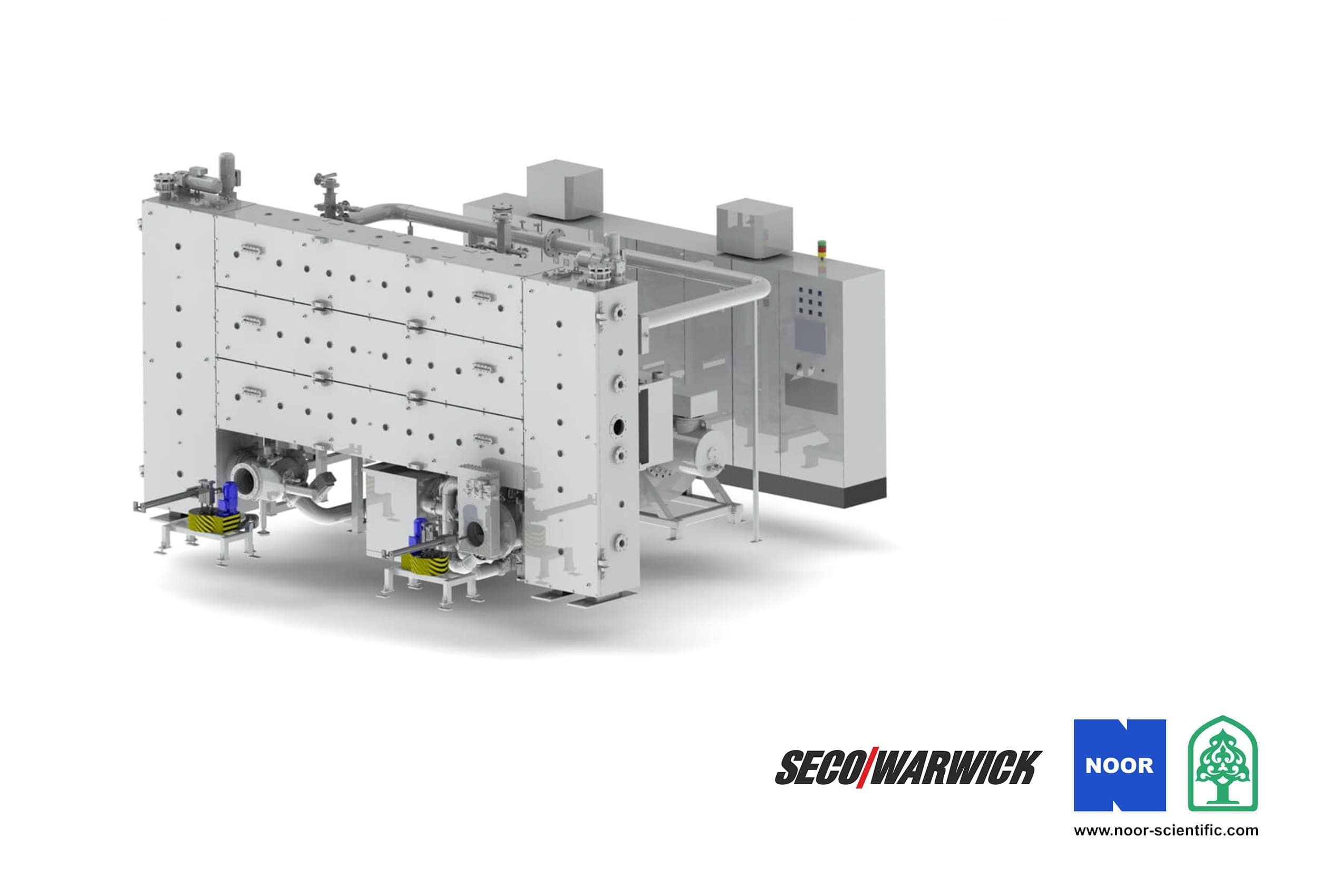

4D Quench® / UniCase Master – Single‑Piece Flow Vacuum Quenching System

A vacuum system for single‑piece nitrogen quenching with distortion control, offering an alternative to press quenching with high repeatability and

VECTOR HV is a horizontally or vertically oriented single-chamber high-vacuum furnace designed for the most demanding heat-treatment applications. It features a graphite or metal hot zone and achieves vacuum levels as low as 10⁻⁸ mbar. The furnace provides uniform 360° radiation heating and supports a wide range of processes including brazing, annealing, solution heat treating, aging, quenching, diffusion bonding, sintering, tempering and outgassing. It offers high process cleanness, consistent workload quality and efficient batch processing with low power and gas consumption. Cooling gases include nitrogen, argon and helium up to 15 bar. VECTOR HV is widely used across industries such as aerospace, energy, nuclear, electronics, automotive and metallurgy.

Designed to meet industrial high-vacuum heat-treatment standards; ready for NADCAP and AMS2750 compliance.

A vacuum system for single‑piece nitrogen quenching with distortion control, offering an alternative to press quenching with high repeatability and

Batch‑type vacuum aluminum brazing furnace for suspended or tray‑loaded components using fluxless magnesium‑activated brazing.

High‑temperature furnaces for purifying graphite using reactive gases under controlled conditions.

High‑efficiency double‑ and triple‑chamber vacuum furnaces designed for low‑pressure carburizing (LPC) and oil or gas quenching, providing high throughput, excellent