VECTOR – Single-chamber Vacuum Furnace with Gas Cooling

Single-chamber horizontal vacuum furnace with high-pressure gas quenching, designed for a wide range of heat treatment processes with high uniformity,

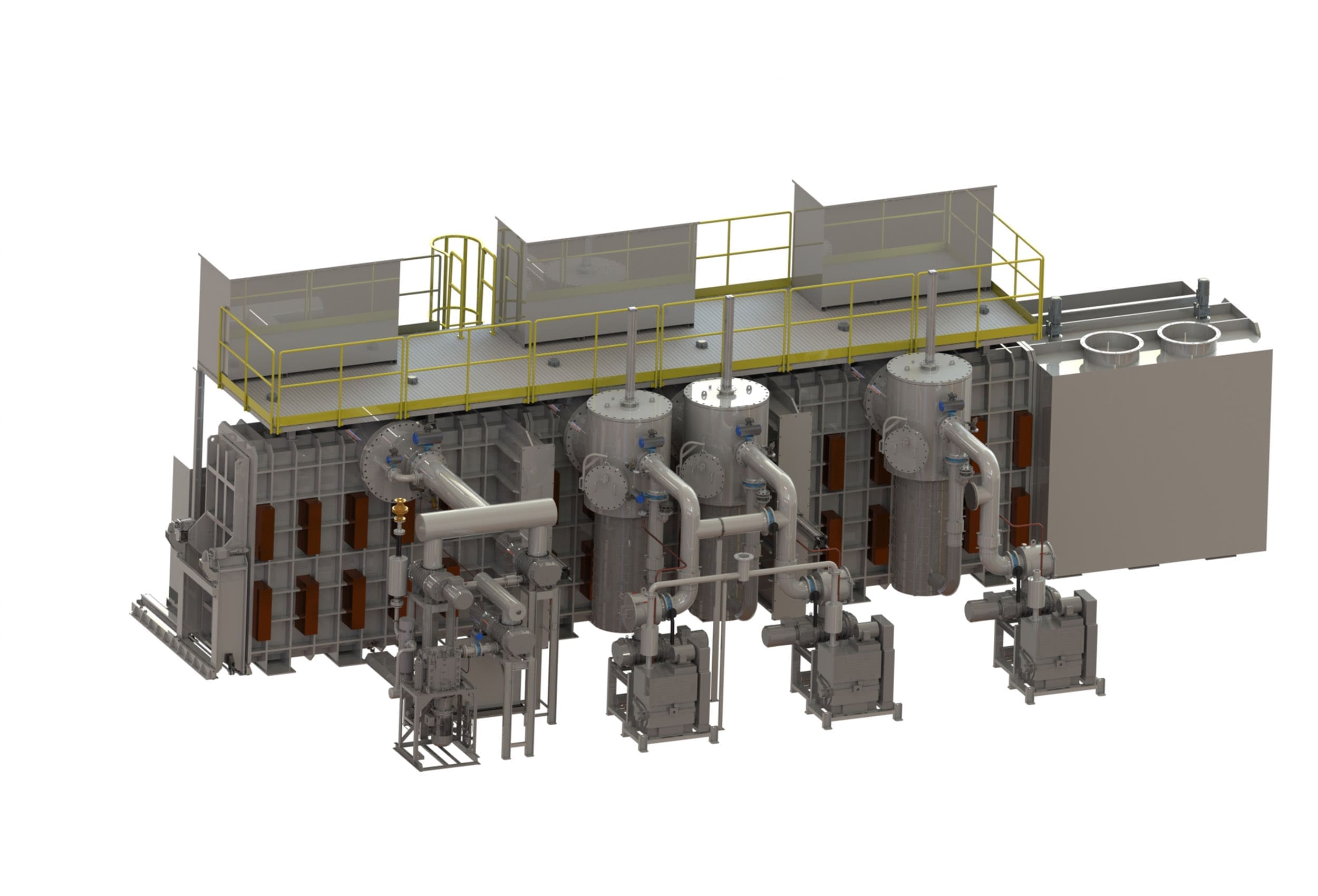

VAB Multi-Chamber systems are continuous vacuum aluminum brazing lines designed for very high-volume production of heat exchangers and complex aluminum assemblies. Multiple connected chambers—typically including pre-heating, brazing, cooling and unloading zones—operate under fluxless brazing conditions using magnesium activation. These systems ensure stable vacuum levels, excellent temperature uniformity and efficient throughput for large-scale HVAC&R, automotive, aerospace and industrial aluminum brazing operations.

Designed to comply with industrial vacuum aluminum-brazing standards.

Single-chamber horizontal vacuum furnace with high-pressure gas quenching, designed for a wide range of heat treatment processes with high uniformity,

Batch‑type vacuum aluminum brazing furnace for suspended or tray‑loaded components using fluxless magnesium‑activated brazing.

High‑temperature furnaces for purifying graphite using reactive gases under controlled conditions.

Vertical pit-type vacuum furnace for low-pressure carburizing (LPC) of large, heavy or long components.