VECTOR 3D – Complete Post‑Processing Vacuum Furnace

Vacuum furnace system engineered for post‑processing of metal 3D‑printed parts, including debinding, sintering and heat‑treatment operations.

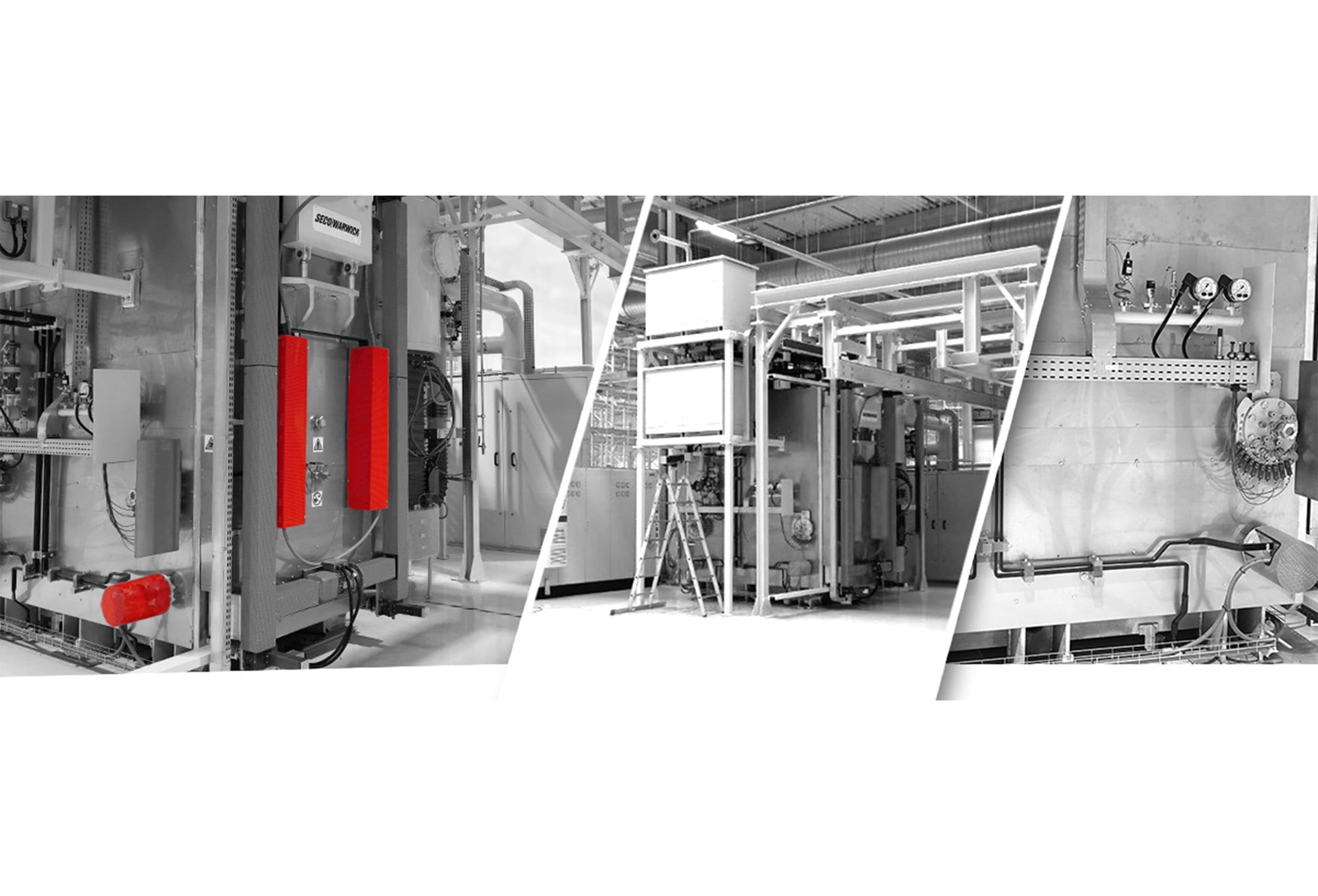

The VAB Universal Chamber Furnace is a single-chamber vacuum aluminum brazing system designed for clean, fluxless brazing of aluminum components, the system provides high vacuum purity, multi-zone temperature control, and optional high-temperature operation. The furnace is equipped with a dedicated loading system and supports precise aluminum brazing by using magnesium activation to remove oxygen and moisture, improving wetting and joint quality. It is suitable for a broad range of industries including HVAC&R, automotive, railway, electronics, generators, and home appliances.

Furnace is designed to meet vacuum aluminum brazing and industrial heat-processing standards.

Vacuum furnace system engineered for post‑processing of metal 3D‑printed parts, including debinding, sintering and heat‑treatment operations.

Furnaces enabling CVI saturation of porous carbon structures with carbon from the gas phase.

A family of flux‑free vacuum aluminum brazing furnaces including multi‑chamber continuous lines, batch tray systems, suspended‑load systems, and oil‑removal furnaces.

Vertical pit-type vacuum furnace for low-pressure carburizing (LPC) of large, heavy or long components.